Here, we describe our commitments towards our Social impact areas, focusing on our ESG Roadmap 2025 commitments.

Achievements

Social

Every leather product, be it a shoe, a bag, or a car seat, is made by humans. It takes many experienced workers to create the perfect leather product, from operators in a chemical plant to leather manufacturers and craftsmen in a shoe factory. As every one of these people fulfils such an important role in our business, providing a safe and healthy workplace for our employees and contractors’ employees and ensuring the safe use of our chemicals are top priorities.

Safe & Healthy workplace:

0 accidents, 0 lost working days and minimized absenteeism

Unfortunately, we had two lost workday cases in 2022. In May, at our Weesp site (NL), an operator hurt his back by tilting an almost empty IBC. In September, at our Montorso site, an operator wounded himself by bumping his head into the roof of a forklift while stepping out of the vehicle. Covid-19, unfortunately, resulted in a higher-than-anticipated Absentee Rate.

Safety & health comes first in all our activities. It is our duty to minimize the various potential risks for our employees inherent to our chemical industry operations as much as possible. The starting point is compliance with all applicable laws and regulations related to H&S at each site, with our Safety, Health & Environment Policy statement as a basis. Our Policy applies to all people working at Royal Smit & Zoon, including contractors.

Our ambition is to create an incident and injury-free work environment, with a target of zero accidents and incidents, backed by zero lost workdays and a minimal absentee rate. To build this strong safety performance across the company, we perform detailed H&S risk assessments via our internal safety risk assessment matrix. We require our employees and contractors to be trained in the appropriate safety risks and skills (defined in a training matrix for each site) and to implement world-class occupational health & safety management systems at all our sites to facilitate continuous improvement (see below KPIs). In addition, specific procedures are followed for the handling of chemicals or hazardous substances (in local languages), and protective equipment is provided to all impacted employees.

Measurement and regular audits (also by local authorities for issuing permits) are part of our continuous improvement journey. Our Global Operations Director is responsible for our SHE Strategy, Policies, Standards, and Procedures. Local SHE Officers are responsible for the implementation at our premises worldwide and supporting all team members in safe working procedures. Through Works Council and/or local SHE committees, employees are consulted on local SHE developments for evaluation.

In the chapter ‘Facts & Figures’, you will find more detailed reporting on the above information and figures regarding a Safe & Healthy Workplace.

Another pivotal aspect of Health & Safety is customer health & safety, assuring the safe use of our chemicals. Our sales and technical teams are our ambassadors to spread this policy to our agent and distributor network as well as to our customers. Sharing our know-how and expertise with the leading industry organizations, with educational institutes in our industry, and in projects we run together with industry partners is another way to safeguard this further. Our commitment to ZDHC and eliminating restricted substances in the value chain, and promoting the Safe Use of Chemicals in Bangladesh, reflect our commitment to minimizing the adverse impact of our products on Health & Safety anywhere in the supply chain. In addition, we issue Safety Data Sheets with our products and implement safety instructions for our traveling team to share with downstream users.

User safety is also integrated into our new product developments. In general, the Project Technical Lead works with Regulatory Affairs from the Scoping phase to start to assess compliance and safety and, where needed, already involve SHE for safety specifically. The key decision point from a safety standpoint is the ‘approval to prepare for scale up’, which means an MoC (Management of Change) needs to be written, discussed, and approved by the Plant Manager. This is the stage where SHE gets a lot more involved in ensuring Safety aspects as met.

2. Number of Injuries per 200.000 worked hours

3. For employees and contractors

4. For employees and contractors

5. Number of Lost Working Days per 200.000 worked hours

6. Percentage of sick days over worked days

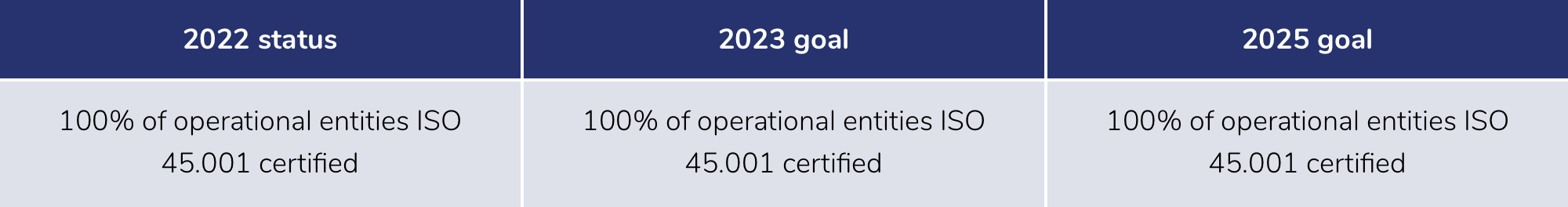

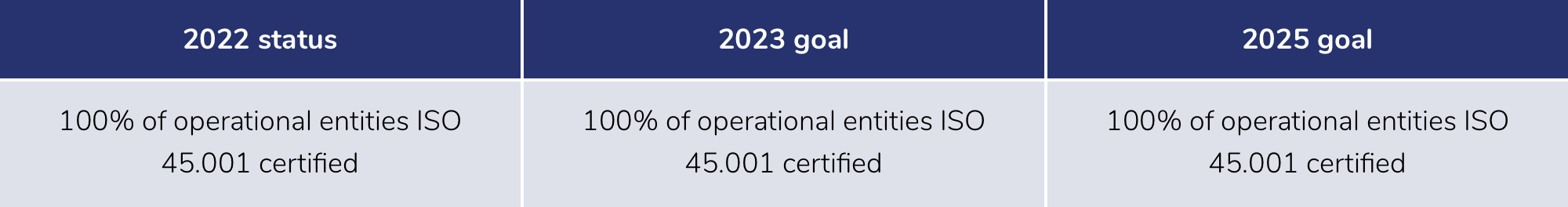

In 2022, our production entity in India obtained ISO 45.001 certification. Based on this reputable certification, all our entities now have world-class social management systems in place. Royal Smit & Zoon views the implementation of its social management system as a process of continuous improvement. According to the Plan-Do-Check-Act Cycle, the ISO 45.001 certification requires ongoing review of our practices, processes, and procedures, periodic internal and external audits to verify and check, and, where needed – improved implementation.

All entities have world class occupational health and safety management systems in place

Education and community involvement are important to demonstrate our thought leadership. We intend to continue taking initiatives building further on the below topics.

Ongoing efforts in education and community involvement, to demonstrate thought leadership

University of Zeology

The University of Zeology provides in-depth and transparent information relating to Zeology and other relevant insight topics like the leather manufacturing process, waste streams, and biodegradability. Besides sharing knowledge, the University of Zeology is also a web section where our opinion on hot topics, such as compostability and the transformation from a linear process to a circular process, can be found.

Knowledge center

Royal Smit & Zoon is convinced that knowledge is more powerful when it’s shared. Knowledge taps into the experience and context of our experts who understand and use that specific data. For Royal Smit & Zoon, transparency and knowledge sharing with customers will improve their user experience. In 2022 we created a special web section on SmitZoon.com to contribute to a broader community and stimulate a continuous learning culture.

Circularity Masterclass

In 2022, Nera Tanning (a subsidiary of Royal Smit & Zoon) hosted a masterclass about circularity. During this masterclass, the circularity of materials and leather was addressed. We looked at which steps need to be taken toward circularity, considering the transition from a linear to a circular process. This masterclass offered insights to over 300 participants from the fashion, footwear, and automotive industries.

Promoting Safe Use of Chemicals

Being a chemical manufacturer, we consider the safe use of chemicals an absolute priority topic. Royal Smit & Zoon is involved in various training efforts and in creating models like the advanced Leather Working Group Protocol 7.2 to promote the safe use of chemicals. In Bangladesh, we have been involved in a 3-year training program, ‘Promoting Safe Use of Chemicals’ (PSUC), in collaboration with TEGEWA. The program ended in 2022; the final training reached over 3,700 leather industry employees (worker and floor level) and showed them how to work safely with chemicals. On our website, you can download the safety guidelines in various languages.

Project for more sustainable chemistry in the leather value chain

Royal Smit & Zoon was an active contributor to the Darmstadt University-led project for more sustainable chemistry in the leather value chain. This publicly funded project focused on the challenges of more sustainable chemistry in the global leather supply chains and included international stakeholders along the supply chains as well as NGOs and academic researchers from various disciplines. The project ended in 2022, and deliverables, among others, led to a Handbook of Leather Design for Sustainable Development, edited by Jonas Rehn-Groenendijk, Karen Lehmann & Julian Schenten (ISBN: 978-3-96187-014-1).

Next Generations

Royal Smit & Zoon is supporting the development of the next generations of leather technicians and educating designers on the knowledge and use of leather. This is done in multiple ways: supporting education within the leather industry, educating designers on leather and the chemistry of leather, and hiring young leather technicians.

In 2022, Royal Smit & Zoon continued to be involved in training and traineeships. Royal Smit & Zoon staff performed as a speaker in international industry events, including an APLF Dubai at the end of March 2022, at the ILM Conference ‘Future Trends in a Post-COVID Leather Industry’ and at the ZDHC conference in India in September 2022. In leather educational institutes, we collaborate with ICLT in the UK, with ITECH in France, and with CLRI in India.

Community involvement

With strong long-term business relations and an extensive customer base in Ukraine and Russia, the Ukraine-Russia war impacted Royal Smit & Zoon directly from a business and human perspective. We felt the urge to support the victims of the war, as it was devastating to watch the humanitarian crisis that this armed conflict brought to so many civilians. In the Netherlands, we refurnished a building in Amsterdam with the support of many employees. Together we turned this building into a home for four Ukrainian families of 30 people, who luckily all found their way around these new circumstances by being employed or continuing their education in the Netherlands. Our Italian entity Codyeco took the opportunity to involve their local community in a humanitarian aid campaign. With the help of many employees, their families and friends, and our local business partners, we collected essential daily supplies such as baby food, hygiene items, clothes, household appliances, and blankets. Sending this supportive aid to Ukraine gave an important message of hope.

In China, we supported five families with essential daily supplies and warm-hearted caring visits. Those families worked in the chemical industry for many years (not in our Company) but - due to illness or inability to work – became impoverished.

We are very grateful that we have supported communities across the globe, reflecting on our thought leadership and our strong sense of responsibility for society. Especially also in this context, ‘every drop makes a difference’ is more than just a slogan.

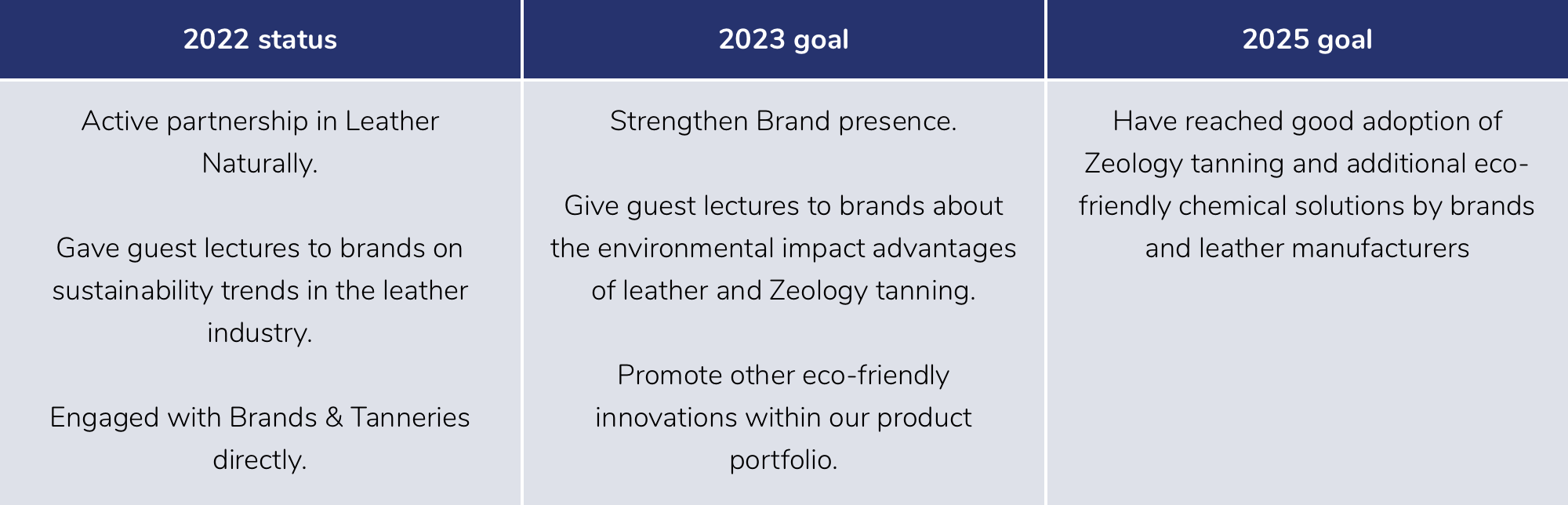

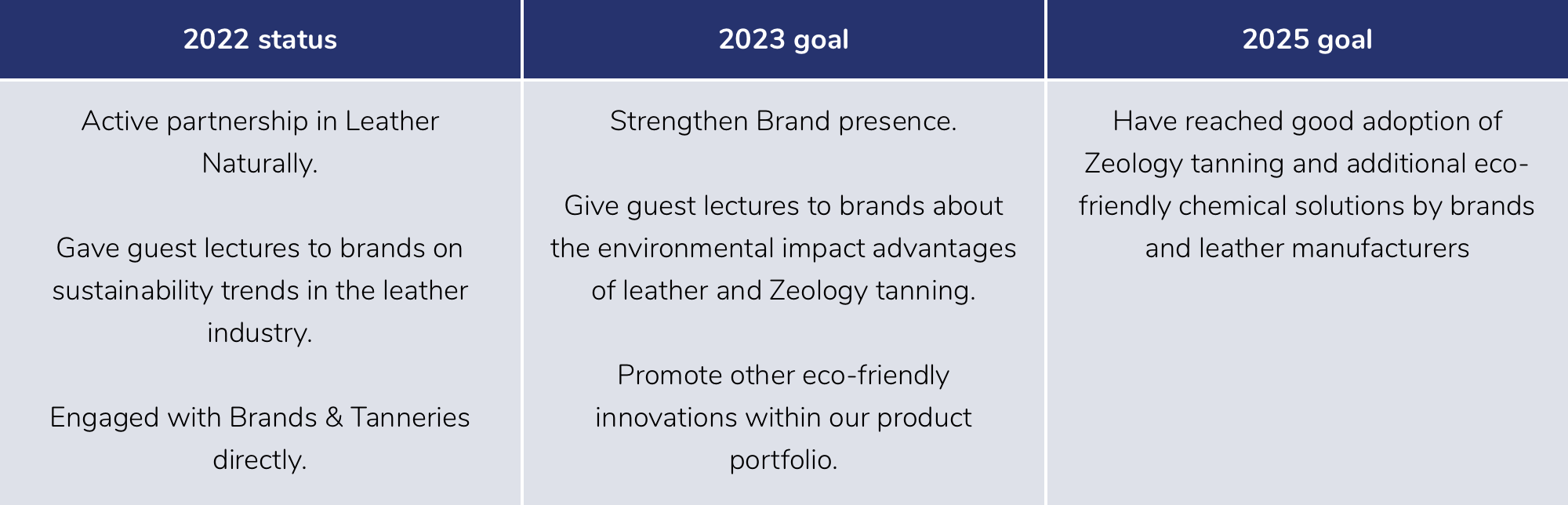

Royal Smit & Zoon is a member of Leather Naturally, which is focusing on education and the promotion of leather to brands, designers, and consumers. During 2022, we supported social media campaigns “#isitleather” and “#chooserealleather”. Both advocate for natural leather by educating consumers, enabling transparency, and ending confusion regarding fake leather alternative products.

We participated in a pilot with Puma to test the first fully compostable shoes called Re:Suede. Only Zeology-tanned leathers, so far, fulfill the industrial compost requirements and allow game-changing thinking and production in the shoe industry worldwide. Ted Louise launched the new Handbag collection promoting the usage of Zeology tanning. Our own internet domain Zeologyleather.com was created for this reason.

We optimized an interactive and informative webpage for brands and designers, where they can easily navigate their way to the nearest Zeology tannery. We want to enable the visitor to select the tannery, not only per region but also on product choice. This is an important step toward servicing our customers better. This optimized webpage also gives our partner tanneries a great platform to profile their business as being part of the Zeology network and to acquire new leads.

Royal Smit & Zoon team members are also actively involved in wider stakeholder and community discussions (LinkedIn, private networks), and we frequently invite brands and designers to our premises to show the beauty and sustainability of leather.

Supporting responsible material decision-making, recognizing leather as an upcycled material with unique sustainable characteristics.

We are actively involved in consumer and brand communication

UN SDG goals

We addressed UN SDGs 6, 8, 12, and 17, and a series of Materiality Matrix topics, including Occupational Health & Safety, Training & Education, and Customer Health & Safety.

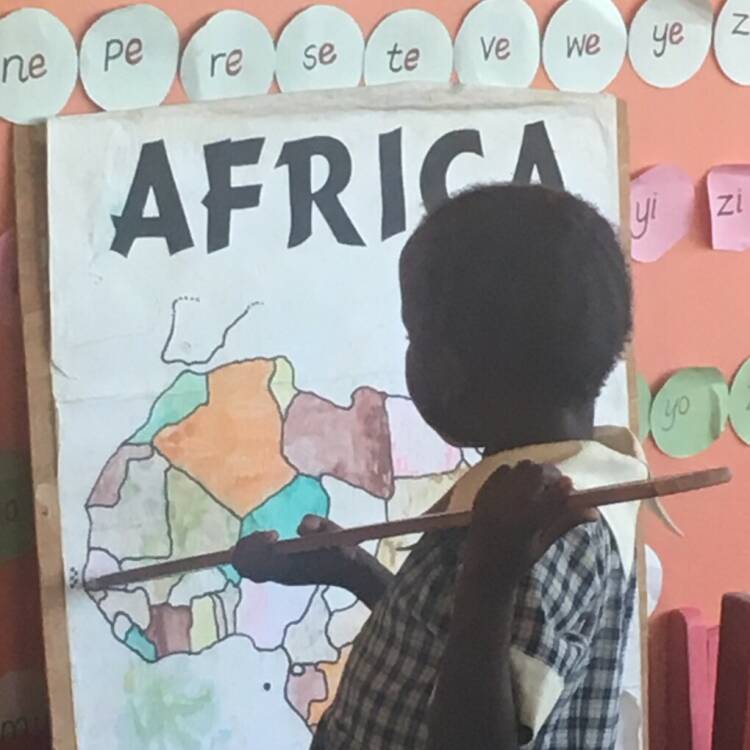

We aim to work towards a society where all people can live a dignified life with equal access to education and healthcare and take control of their own future. With this mission in mind, Joost Smit, the 6th generation owner of Royal Smit & Zoon, set up the Koornzaayer Foundation in 1969. The foundation - named after the ship our founder Albert Smit was the captain of in 1821 - supports local initiatives on education and health care projects in Kenya and Uganda.

The Koornzaayer Foundation

- Education to give children an opportunity to make changes in their own country that will also benefit the next generation.

- Health care in order to be able to learn and go to school.

In 2022, like in the rest of the world, Covid-19 and its aftermath were unfortunately still very present around our projects. The Koornzaayer Foundation chose to support her working partners throughout this period.

In the 50 years of its existence, the Koornzaayer Foundation has ignited and supported dozens of local initiatives related to these two central themes:

Kenya

In Kenya, we continued our collaboration with Victoria Friendly Foundations, a group of local villagers on Rusinga Island, off the Kenyan Lake Victoria coast. We teamed up in 2014 and are still collaborating on projects to meet the basic needs of orphaned and needy children on the island.

In our previous reports, we mentioned our joint interest in further improving the effectiveness of food security together with VOX impulse and the Koornzaayer Foundation. The defined focus is on securing access to safe and sustainable water sources that are manageable by the communities themselves, being a crucial means for food security.

Uganda

In Uganda, the effect of one of the hardest Covid-19 lockdowns was felt in the children’s participation rate in education. Especially a disproportionate amount of girls did not – or only a limited amount of time - return to school after the lockdowns. Many parents have lost their jobs and lost belief in education as a whole.

Community involvement

With strong long-term business relations and an extensive customer base in Ukraine and Russia, the Ukraine-Russia war impacted Royal Smit & Zoon directly from a business and human perspective. We felt the urge to support the victims of the war, as it was devastating to watch the humanitarian crisis that this armed conflict brought to so many civilians. In the Netherlands, we refurnished a building in Amsterdam with the support of many employees. Together we turned this building into a home for four Ukrainian families of 30 people, who luckily all found their way around these new circumstances by being employed or continuing their education in the Netherlands. Our Italian entity Codyeco took the opportunity to involve their local community in a humanitarian aid campaign. With the help of many employees, their families and friends, and our local business partners, we collected essential daily supplies such as baby food, hygiene items, clothes, household appliances, and blankets. Sending this supportive aid to Ukraine gave an important message of hope.

In China, we supported five families with essential daily supplies and warm-hearted caring visits. Those families worked in the chemical industry for many years (not in our Company) but - due to illness or inability to work – became impoverished.

We are very grateful that we have supported communities across the globe, reflecting on our thought leadership and our strong sense of responsibility for society. Especially also in this context, ‘every drop makes a difference’ is more than just a slogan.

Project for more sustainable chemistry in the leather value chain

Royal Smit & Zoon was an active contributor to the Darmstadt University-led project for more sustainable chemistry in the leather value chain. This publicly funded project focused on the challenges of more sustainable chemistry in the global leather supply chains and included international stakeholders along the supply chains as well as NGOs and academic researchers from various disciplines. The project ended in 2022, and deliverables, among others, led to a Handbook of Leather Design for Sustainable Development, edited by Jonas Rehn-Groenendijk, Karen Lehmann & Julian Schenten (ISBN: 978-3-96187-014-1).

Promoting Safe Use of Chemicals

Being a chemical manufacturer, we consider the safe use of chemicals an absolute priority topic. Royal Smit & Zoon is involved in various training efforts and in creating models like the advanced Leather Working Group Protocol 7.2 to promote the safe use of chemicals. In Bangladesh, we have been involved in a 3-year training program, ‘Promoting Safe Use of Chemicals’ (PSUC), in collaboration with TEGEWA. The program ended in 2022; the final training reached over 3,700 leather industry employees (worker and floor level) and showed them how to work safely with chemicals. On our website, you can download the safety guidelines in various languages.

Every leather product, be it a shoe, a bag, or a car seat, is made by humans. It takes many experienced workers to create the perfect leather product, from operators in a chemical plant to leather manufacturers and craftsmen in a shoe factory. As every one of these people fulfils such an important role in our business, providing a safe and healthy workplace for our employees and contractors’ employees and ensuring the safe use of our chemicals are top priorities.

Please swipe to view full table

In 2022, our production entity in India obtained ISO 45.001 certification. Based on this reputable certification, all our entities now have world-class social management systems in place. Royal Smit & Zoon views the implementation of its social management system as a process of continuous improvement. According to the Plan-Do-Check-Act Cycle, the ISO 45.001 certification requires ongoing review of our practices, processes, and procedures, periodic internal and external audits to verify and check, and, where needed – improved implementation.

All entities have world class occupational health and safety management systems in place

In the North, we continued working with our local partner, Link To Progress, on water management, hygiene, sanitation, and counseling. In previous years, we supported strengthening the fundraising department of Link To Progress to offer them a way out of their dependency on foreign donors. The Koornzaayer Foundation is pleased that they were able to find new potential donors to not only continue their current work but also to expand the work field. Many efforts are needed in the coming years to get all the kids back in school.

Next to Link To Progress, we continued supporting two of our other partners. Nurture Africa is a small clinic with an outreach educational program in the community, also focusing on hygiene management and food security. Children's Welfare Mission (Kinderhulp Afrika) has its own boarding school. Primarily only for orphans and secondary also for children whose parents can afford the fees. What makes them unique is that all children not only reach their ordinary O or A levels but also finish secondary school with a certificate for an occupation. So that means every child will leave school with a degree in either tailoring, carpentry, solar mechanics, catering, plumbing, etc. For the last three years, they have faced the problem that they were unable to pay the salaries of their outstanding and loyal staff. In this, we decided to help them. By 2023, we hope that all kids will go back to school and start learning again. It’s the only way a future generation can change things for the better.

Uganda

In Uganda, the effect of one of the hardest Covid-19 lockdowns was felt in the children’s participation rate in education. Especially a disproportionate amount of girls did not – or only a limited amount of time - return to school after the lockdowns. Many parents have lost their jobs and lost belief in education as a whole.

In 2022, the research for options of getting water connections on the island was concluded, and our local partners discussed the outcome with the local government, the community, and all others that needed to be involved. Based on the research results and outcome of discussions, it was decided to work with a local party that can install and manage a water distribution system, home connections, and water meters at each home. At the end of 2022, we started the model on a small scale by constructing the full system for several homes. Our goal is to have this completed and tested during 2023. From 2024 onwards, we can scale up the model and increase the number of connected homes. The end goal is to provide the whole 35,000-people population with access to healthy water for their hygiene and for irrigation. This way, we can improve food security, the diversification of income sources, and, not unimportantly, we hope to combat erosion on the island.

All these initiatives and plans perfectly fit within our achievements to date. Central to this: an integrated early childhood development education package that has been successfully integrated into the community. The school building not only offers proper education but also includes a feeding program, health activities, and, indirectly, food security and economic development.

The integrated community development program is a six-year program that is the joint initiative of the Victoria Friendly Montessori, De Koornzaayer Foundation, FEMI, Talud, Imani Foundation, the Catz Charity Foundation, and the Peter van Vliet Foundation. All of us envision a community with a diversification of income sources and healthy and stable homes where children can grow and develop into adults that can make a difference in their community.

Kenya

In Kenya, we continued our collaboration with Victoria Friendly Foundations, a group of local villagers on Rusinga Island, off the Kenyan Lake Victoria coast. We teamed up in 2014 and are still collaborating on projects to meet the basic needs of orphaned and needy children on the island.

In our previous reports, we mentioned our joint interest in further improving the effectiveness of food security together with VOX impulse and the Koornzaayer Foundation. The defined focus is on securing access to safe and sustainable water sources that are manageable by the communities themselves, being a crucial means for food security.

- Education to give children an opportunity to make changes in their own country that will also benefit the next generation.

- Health care in order to be able to learn and go to school.

In 2022, like in the rest of the world, Covid-19 and its aftermath were unfortunately still very present around our projects. The Koornzaayer Foundation chose to support her working partners throughout this period.

In the 50 years of its existence, the Koornzaayer Foundation has ignited and supported dozens of local initiatives related to these two central themes:

We aim to work towards a society where all people can live a dignified life with equal access to education and healthcare and take control of their own future. With this mission in mind, Joost Smit, the 6th generation owner of Royal Smit & Zoon, set up the Koornzaayer Foundation in 1969. The foundation - named after the ship our founder Albert Smit was the captain of in 1821 - supports local initiatives on education and health care projects in Kenya and Uganda.

The Koornzaayer Foundation

UN SDG goals

We addressed UN SDGs 6, 8, 12, and 17, and a series of Materiality Matrix topics, including Occupational Health & Safety, Training & Education, and Customer Health & Safety.

Please swipe to view full table

Royal Smit & Zoon is a member of Leather Naturally, which is focusing on education and the promotion of leather to brands, designers, and consumers. During 2022, we supported social media campaigns “#isitleather” and “#chooserealleather”. Both advocate for natural leather by educating consumers, enabling transparency, and ending confusion regarding fake leather alternative products.

We participated in a pilot with Puma to test the first fully compostable shoes called Re:Suede. Only Zeology-tanned leathers, so far, fulfill the industrial compost requirements and allow game-changing thinking and production in the shoe industry worldwide. Ted Louise launched the new Handbag collection promoting the usage of Zeology tanning. Our own internet domain Zeologyleather.com was created for this reason.

We optimized an interactive and informative webpage for brands and designers, where they can easily navigate their way to the nearest Zeology tannery. We want to enable the visitor to select the tannery, not only per region but also on product choice. This is an important step toward servicing our customers better. This optimized webpage also gives our partner tanneries a great platform to profile their business as being part of the Zeology network and to acquire new leads.

Royal Smit & Zoon team members are also actively involved in wider stakeholder and community discussions (LinkedIn, private networks), and we frequently invite brands and designers to our premises to show the beauty and sustainability of leather.

Supporting responsible material decision-making, recognizing leather as an upcycled material with unique sustainable characteristics.

We are actively involved in consumer and brand communication

Next Generations

Royal Smit & Zoon is supporting the development of the next generations of leather technicians and educating designers on the knowledge and use of leather. This is done in multiple ways: supporting education within the leather industry, educating designers on leather and the chemistry of leather, and hiring young leather technicians.

In 2022, Royal Smit & Zoon continued to be involved in training and traineeships. Royal Smit & Zoon staff performed as a speaker in international industry events, including an APLF Dubai at the end of March 2022, at the ILM Conference ‘Future Trends in a Post-COVID Leather Industry’ and at the ZDHC conference in India in September 2022. In leather educational institutes, we collaborate with ICLT in the UK, with ITECH in France, and with CLRI in India.

Circularity Masterclass

In 2022, Nera Tanning (a subsidiary of Royal Smit & Zoon) hosted a masterclass about circularity. During this masterclass, the circularity of materials and leather was addressed. We looked at which steps need to be taken toward circularity, considering the transition from a linear to a circular process. This masterclass offered insights to over 300 participants from the fashion, footwear, and automotive industries.

Knowledge center

Royal Smit & Zoon is convinced that knowledge is more powerful when it’s shared. Knowledge taps into the experience and context of our experts who understand and use that specific data. For Royal Smit & Zoon, transparency and knowledge sharing with customers will improve their user experience. In 2022 we created a special web section on SmitZoon.com to contribute to a broader community and stimulate a continuous learning culture.

University of Zeology

The University of Zeology provides in-depth and transparent information relating to Zeology and other relevant insight topics like the leather manufacturing process, waste streams, and biodegradability. Besides sharing knowledge, the University of Zeology is also a web section where our opinion on hot topics, such as compostability and the transformation from a linear process to a circular process, can be found.

Please swipe to view full table

Education and community involvement are important to demonstrate our thought leadership. We intend to continue taking initiatives building further on the below topics.

Ongoing efforts in education and community involvement, to demonstrate thought leadership

2. Number of Injuries per 200.000 worked hours

3. For employees and contractors

4. For employees and contractors

5. Number of Lost Working Days per 200.000 worked hours

6. Percentage of sick days over worked days

Please swipe to view full table

Safe & Healthy workplace:

0 accidents, 0 lost working days and minimized absenteeism

Unfortunately, we had two lost workday cases in 2022. In May, at our Weesp site (NL), an operator hurt his back by tilting an almost empty IBC. In September, at our Montorso site, an operator wounded himself by bumping his head into the roof of a forklift while stepping out of the vehicle. Covid-19, unfortunately, resulted in a higher-than-anticipated Absentee Rate.

Safety & health comes first in all our activities. It is our duty to minimize the various potential risks for our employees inherent to our chemical industry operations as much as possible. The starting point is compliance with all applicable laws and regulations related to H&S at each site, with our Safety, Health & Environment Policy statement as a basis. Our Policy applies to all people working at Royal Smit & Zoon, including contractors.

Our ambition is to create an incident and injury-free work environment, with a target of zero accidents and incidents, backed by zero lost workdays and a minimal absentee rate. To build this strong safety performance across the company, we perform detailed H&S risk assessments via our internal safety risk assessment matrix. We require our employees and contractors to be trained in the appropriate safety risks and skills (defined in a training matrix for each site) and to implement world-class occupational health & safety management systems at all our sites to facilitate continuous improvement (see below KPIs). In addition, specific procedures are followed for the handling of chemicals or hazardous substances (in local languages), and protective equipment is provided to all impacted employees.

Measurement and regular audits (also by local authorities for issuing permits) are part of our continuous improvement journey. Our Global Operations Director is responsible for our SHE Strategy, Policies, Standards, and Procedures. Local SHE Officers are responsible for the implementation at our premises worldwide and supporting all team members in safe working procedures. Through Works Council and/or local SHE committees, employees are consulted on local SHE developments for evaluation.

In the chapter ‘Facts & Figures’, you will find more detailed reporting on the above information and figures regarding a Safe & Healthy Workplace.

Another pivotal aspect of Health & Safety is customer health & safety, assuring the safe use of our chemicals. Our sales and technical teams are our ambassadors to spread this policy to our agent and distributor network as well as to our customers. Sharing our know-how and expertise with the leading industry organizations, with educational institutes in our industry, and in projects we run together with industry partners is another way to safeguard this further. Our commitment to ZDHC and eliminating restricted substances in the value chain, and promoting the Safe Use of Chemicals in Bangladesh, reflect our commitment to minimizing the adverse impact of our products on Health & Safety anywhere in the supply chain. In addition, we issue Safety Data Sheets with our products and implement safety instructions for our traveling team to share with downstream users.

User safety is also integrated into our new product developments. In general, the Project Technical Lead works with Regulatory Affairs from the Scoping phase to start to assess compliance and safety and, where needed, already involve SHE for safety specifically. The key decision point from a safety standpoint is the ‘approval to prepare for scale up’, which means an MoC (Management of Change) needs to be written, discussed, and approved by the Plant Manager. This is the stage where SHE gets a lot more involved in ensuring Safety aspects as met.

Here, we describe our commitments towards our Social impact areas, focusing on our ESG Roadmap 2025 commitments.

Achievements

Social