Here, we describe our commitments towards the environment, focusing on our ESG Roadmap 2025 commitments.

Achievements

Environment

Our product range is ZDHC compliant and certified

Royal Smit & Zoon has been a contributor to the ZDHC (Zero Discharge of Hazardous Chemicals) Foundation since 2018 and strongly supports their mission to create a supply chain towards safer chemistry. In 2019, our first products were certified according to the ZDHC Conformance Level 3, and since then we included our key range in this program. Our complete product range is ZDHC compliant, whereby the % represents the volume of products certified by an independent third party. Our 2022 status is lower than the target (85%) due to an increase in new products not certified and the aftermath of Covid-19 travel limitations, restricting third-party auditing opportunities in Asia.

The basis for future compliance is our internal Restricted Substances List (RSL). This is a list of substances not present in any of our products. A steering group reviews and updates the Royal Smit & Zoon RSL annually, taking into account the following sources and criteria: Candidate List of Substances of Very High Concern (ECHA); Authorization List (Appendix XIV of REACh); List of Restrictions (Appendix XVIII of REACh); Manufacturing Restricted Substances List (MRSL of ZDHC). The Royal Smit & Zoon RSL remained unchanged, apart from changes in the official EU lists and the ZDHC MRSL version 3.0, which were, of course, included. Additionally, we are proactively phasing out unwanted substances that are not (yet) on the list of restricted substances. Substances to be phased out are selected based on their hazard and information from the market.

% based on volume sold

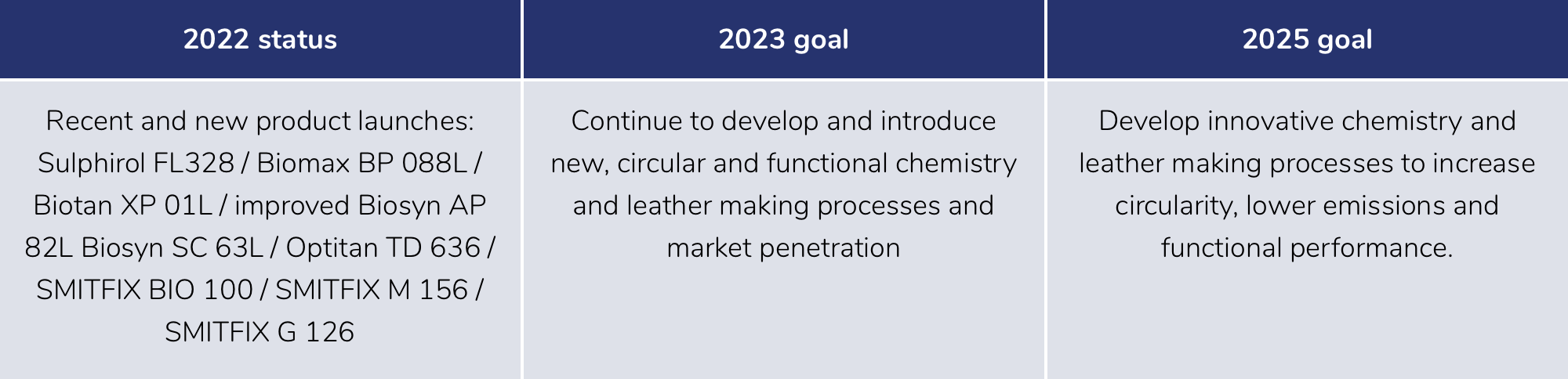

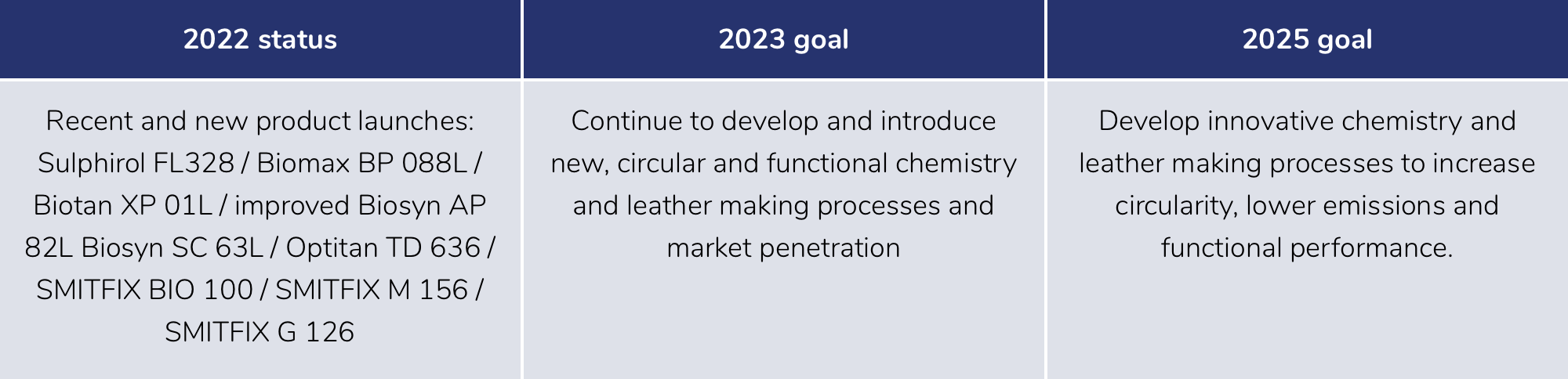

Innovation is at the heart of our strategy, and we are on track to develop best-in-class chemistry. In recent years, several new patents have been registered, updates to our Product Passport have been made, and experiences have been widened with techniques like Life Cycle Assessments, wastewater guidelines, biodegradability, compostability, and circularity in general. This has led to several innovations in recent years that are currently being marketed. A selection is described below.

Develop innovative chemistry and leather-making processes to increase circularity

For Nera, 2022 was the year of Zeology adoption. In 2021, Zeology, the chrome, heavy metal, and aldehyde-free tanning agent based on modified zeolite, was introduced to tanneries all over the world. In 2022, we further developed the tanning and crusting activities with these Zeology partners. By now, more than 100 tanneries in Europe, Asia, North and South America, and Africa are working with Zeology. Examples are; Bader, Südleder, Slovtan, Scan-Hide, Gruppo Mastrotto, Uyguner, CPL, and Tasman Leather (for others, please visit Zeology Leather Suppliers - Nera Tanning). In 2021, most of the work was done on small-scale trials, but now, many tanneries have completed their R&D and can run on a production scale. Many have initiated sampling and sales of Zeology-based leather articles to brands and car manufacturers. Although most brands looking into Zeology adoption do not communicate on this (yet), others do, e.g., Ted Louise, Puma, Dugros, Anya Hindmarch, Italic, and Emma Safety Footwear. With this, Zeology is increasingly driving a significant impact in making the leather value chain more sustainable. You can find more information on brand engagement under ‘Social’.

While supporting our tannery partners, the interest of fashion and automotive brands for Zeology has also increased significantly. As a result, our interaction with brands and car manufacturers (OEMs) increased significantly in 2022. Through these direct contact moments at fashion fairs, automotive shows, and online and live meetings, we were able, while respecting the position of our customers, to convey the details and backgrounds of Zeology (leather). Instead of promoting Zeology as the best alternative to chrome and glutardialdehyde, we have rather helped brands and OEMs to make well-informed decisions and avoid regrettable choices. It is clear that the leather landscape is rapidly changing, caused, e.g., by the pressure on chrome use, the ECHA looking into the use of glutardialdehyde (GDA), and the offering of biobased leather alternatives combined with plastics.

Sharing knowledge and evidence for our claims and being transparent are crucial aspects. For that reason, Nera focused on sharing information through our website, whitepapers, organizing Masterclasses, and obtaining certifications proving Zeology is a sustainable solution. Besides SHE-related certifications such as a ‘ZDHC MRSL level 3 certificate’, a ‘Cradle-to-Cradle Material Health certificate’ (part of a full Cradle-to-cradle certification), and a ‘ToxFMD Screened Chemistry certificate’, Nera has completed a ‘Cradle-to-cradle Life Cycle Analyses (LCA)’ for the Zeology tanning product in 2022. Nera uses the LCA data to plan and realize further impact improvements for future Zeology developments.

Objective: Supporting the leather industry, tanneries, fashion, and automotive brands, with a sustainable and versatile alternative to chrome and GDA tanning.

Zeology – The sustainable and versatile alternative to chrome and GDA tanning

Lignin modified re-tanning agents

Objective: Improving the renewability

Biopolymers based on sugar beet pectins

Objective: Creating bio-based ingredients

Bio-based Polyurethanes

Objective: Creating bio-based ingredients

Optitan

Objective: Minimizing the environmental impact, while optimizing leather performance

Basetone White

Ti-Free

Objective: Eliminating hazardous substances from our product range

Sulphirol FL328

Objective: Minimizing the environmental impact while optimizing leather performance

Biopolymers from LIFE Biopol

Objective: Creating bio-based ingredients

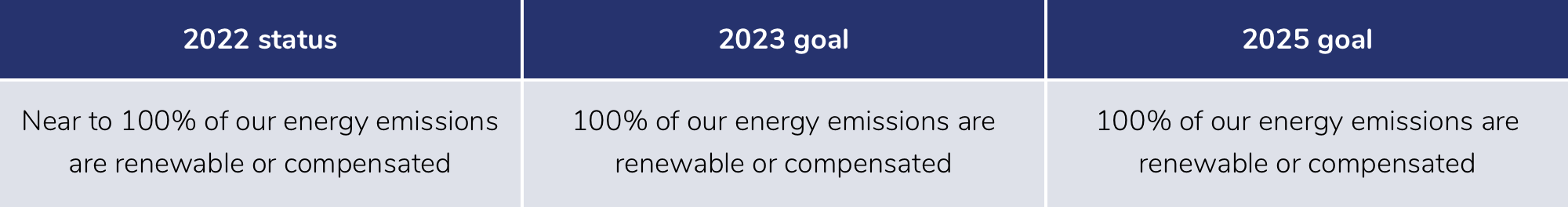

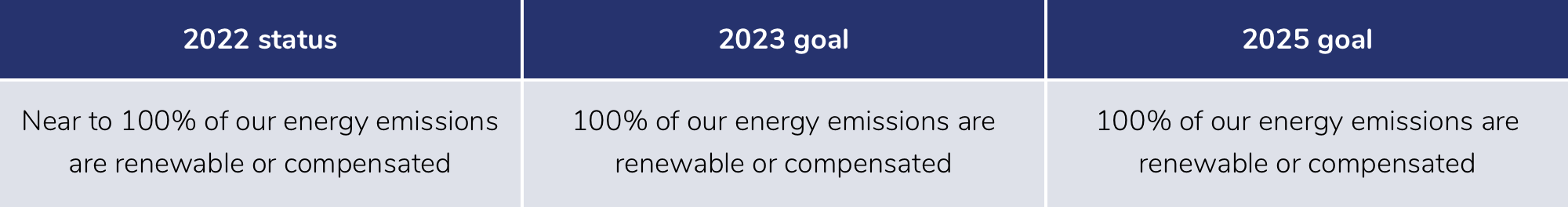

Royal Smit & Zoon is using certification programs including the Gold Standard Verified Emission Reductions (VERs) and the purchase of certificates of Sustainable Energy for all of its factories.

The urgent need to combat climate change, expected EU and national regulations on energy consumption and Greenhouse Gas (GHG) emissions, and steeply increasing energy market prices, made us start a new round of energy reduction actions in 2022. Enhanced attention to ‘good housekeeping’ measures and replacing old electrical equipment with more energy-efficient new equipment resulted in further reductions in energy consumption. Investigations were initiated to identify new opportunities for improving the energy efficiency of processes and equipment. These investigations will be ended in 2023 and used for setting up a multi-year energy reduction program.

Our energy consumption is renewable or compensated

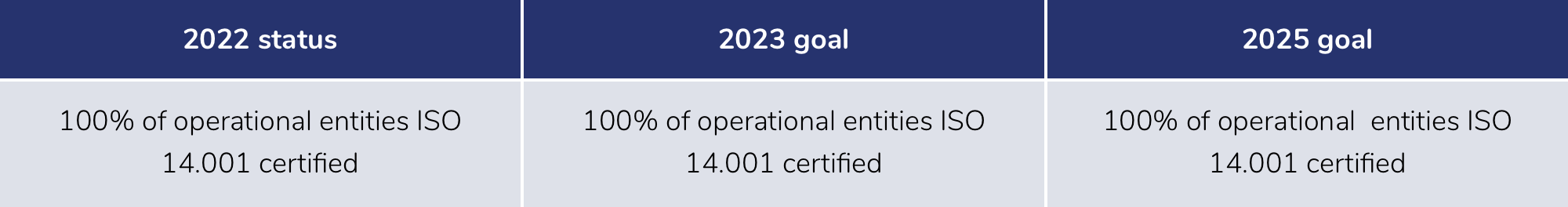

In 2022, our production entities in India obtained ISO 14.001 certification. Based on this reputable certification, all our entities now have world-class environmental management systems in place. Royal Smit & Zoon views the implementation of its environmental management system as a process of continuous improvement. According to the Plan-Do-Check-Act Cycle, the ISO 14.001 certification requires ongoing reviews of our practices, processes, and procedures, periodic internal or external audits to verify and check, and where needed – improved implementation.

All entities have world-class environmental management systems in place

UN SDG goals

We addressed UN SDGs 6, 8, 12, 13, and 17 and a series of Materiality Matrix topics, including Occupational Health & Safety, Effluents & Waste, Water & Effluents, Materials, Environmental Compliance, Economic Performance, Customer Health & Safety, Emissions, Energy.

In 2020, Royal Smit & Zoon completed the LIFE Biopol project and launched the products. In 2022 we completed an upgrade of the original products to increase the production process to make it safer, as well as increasing the biobased content to 94% for the Biosyn AP 82L and Biosyn SC63L.

For Nera, 2022 was the year of Zeology adoption. In 2021, Zeology, the chrome, heavy metal, and aldehyde-free tanning agent based on modified zeolite, was introduced to tanneries all over the world. In 2022, we further developed the tanning and crusting activities with these Zeology partners. By now, more than 100 tanneries in Europe, Asia, North and South America, and Africa are working with Zeology. Examples are; Bader, Südleder, Slovtan, Scan-Hide, Gruppo Mastrotto, Uyguner, CPL, and Tasman Leather (for others, please visit Zeology Leather Suppliers - Nera Tanning). In 2021, most of the work was done on small-scale trials, but now, many tanneries have completed their R&D and can run on a production scale. Many have initiated sampling and sales of Zeology-based leather articles to brands and car manufacturers. Although most brands looking into Zeology adoption do not communicate on this (yet), others do, e.g., Ted Louise, Puma, Dugros, Anya Hindmarch, Italic, and Emma Safety Footwear. With this, Zeology is increasingly driving a significant impact in making the leather value chain more sustainable. You can find more information on brand engagement under ‘Social’.

While supporting our tannery partners, the interest of fashion and automotive brands for Zeology has also increased significantly. As a result, our interaction with brands and car manufacturers (OEMs) increased significantly in 2022. Through these direct contact moments at fashion fairs, automotive shows, and online and live meetings, we were able, while respecting the position of our customers, to convey the details and backgrounds of Zeology (leather). Instead of promoting Zeology as the best alternative to chrome and glutardialdehyde, we have rather helped brands and OEMs to make well-informed decisions and avoid regrettable choices. It is clear that the leather landscape is rapidly changing, caused, e.g., by the pressure on chrome use, the ECHA looking into the use of glutardialdehyde (GDA), and the offering of biobased leather alternatives combined with plastics.

Sharing knowledge and evidence for our claims and being transparent are crucial aspects. For that reason, Nera focused on sharing information through our website, whitepapers, organizing Masterclasses, and obtaining certifications proving Zeology is a sustainable solution. Besides SHE-related certifications such as a ‘ZDHC MRSL level 3 certificate’, a ‘Cradle-to-Cradle Material Health certificate’ (part of a full Cradle-to-cradle certification), and a ‘ToxFMD Screened Chemistry certificate’, Nera has completed a ‘Cradle-to-cradle Life Cycle Analyses (LCA)’ for the Zeology tanning product in 2022. Nera uses the LCA data to plan and realize further impact improvements for future Zeology developments.

% based on volume sold

UN SDG goals

We addressed UN SDGs 6, 8, 12, 13, and 17 and a series of Materiality Matrix topics, including Occupational Health & Safety, Effluents & Waste, Water & Effluents, Materials, Environmental Compliance, Economic Performance, Customer Health & Safety, Emissions, Energy.

Please swipe to view full table

In 2022, our production entities in India obtained ISO 14.001 certification. Based on this reputable certification, all our entities now have world-class environmental management systems in place. Royal Smit & Zoon views the implementation of its environmental management system as a process of continuous improvement. According to the Plan-Do-Check-Act Cycle, the ISO 14.001 certification requires ongoing reviews of our practices, processes, and procedures, periodic internal or external audits to verify and check, and where needed – improved implementation.

All entities have world-class environmental management systems in place

Please swipe to view full table

Royal Smit & Zoon is using certification programs including the Gold Standard Verified Emission Reductions (VERs) and the purchase of certificates of Sustainable Energy for all of its factories.

The urgent need to combat climate change, expected EU and national regulations on energy consumption and Greenhouse Gas (GHG) emissions, and steeply increasing energy market prices, made us start a new round of energy reduction actions in 2022. Enhanced attention to ‘good housekeeping’ measures and replacing old electrical equipment with more energy-efficient new equipment resulted in further reductions in energy consumption. Investigations were initiated to identify new opportunities for improving the energy efficiency of processes and equipment. These investigations will be ended in 2023 and used for setting up a multi-year energy reduction program.

Our energy consumption is renewable or compensated

Biopolymers from LIFE Biopol

Objective: Creating bio-based ingredients

As an improved version of the versatile classic Smit Wet End product Synthol FL 327, a more bio-based fatliquor for extreme soft leather was launched in 2022. The product gives a soft and airy fullness and has 70% bio-based content, up from 10%, with a good heat yellowing and lightfastness profile

Sulphirol FL328

Objective: Minimizing the environmental impact while optimizing leather performance

This white pigment is formulated with insoluble inorganic and non-harmful substances and is 100% free of TiO2. The technology of Basetone White Ti-free enables reaching very high covering power and excellent physical fastness properties without losing refraction-index with a consequent great white intensity. Due to its special formulation, this pigment fits perfectly when used on metal-free white leather following ISO specification 15115: 2019.

Basetone White

Ti-Free

Objective: Eliminating hazardous substances from our product range

In 2020, the Optitan range was introduced. In 2021, the whole range is updated and assessed for bisphenol and will allow for leather that meets the upcoming bisphenol requirements. Another update was completed in early 2022, resulting in low-bisphenol Optitan TD 636 liquid and powder. With the current bisphenol-level proposals pending, Royal Smit & Zoon is looking further to expand the range of Optitans.

Optitan

Objective: Minimizing the environmental impact, while optimizing leather performance

Royal Smit & Zoon has launched SMITFIX BIO 100 (Bio-Based Polyurethanes for basecoat) and SMITFIX M 156 & SMITFIX G 126, which are two partially bio-based polyurethanes. Polyurethanes are among the most versatile and commonly used polymers in the world. With current technology, it is possible to move to partially renewable and sustainable bio-based carbon content. This is feasible by adding bio-based carbon content and reducing CO2 emissions by using bio polyol.

Bio polyol or natural oil polyol (NOP) is synthesized from various vegetable oils and other renewable sources, which are a by-product in the pulp and paper industry. Bio polyol offers a higher bio-based carbon content and a reduction in CO2 emissions.

Bio-based Polyurethanes

Objective: Creating bio-based ingredients

At the beginning of 2022, Royal Smit & Zoon launched its new 100% biobased and readily biodegradable product Biomax BP 088L. This circular innovation was achieved in cooperation with Wageningen University Food & Biobased Research, Royal Cosun, and other partners in a research consortium. The Biomax BP 088L is a substitute for fossil fuel-based and non-biodegradable polymers in chemicals for the wet-end production process. Biomax BP 088L also positively influences the characteristics of leather, especially its color intensity. Biomax BP 088L is being adopted by leading tanneries across continents, such as Pasubio Leather in Italy and Tasman Tannery in New Zealand, for both its performance as its bio-based structure and the first articles with the products are at brands for review.

Biopolymers based on sugar beet pectins

Objective: Creating bio-based ingredients

In December 2022, Royal Smit & Zoon made a full industrial-scale production of the Smit Biotan XP 01L, which is a chemical incorporating lignins in phenolic re-tanning agents. The aim is to increase the renewable content by partially replacing phenol with industrial lignins and possibly improve the biodegradability of phenolic syntans. The emissions profile on phenol, formaldehyde, and bisphenols of this novel product is excellent, and Biotan XP 01L combines the benefits of a phenolic re-tanning agent with bisphenol levels < 10 ppm. The leather performance of this partially biobased product is comparable to traditional retanning chemicals built from fossil fuels. The launch is expected in early 2023.

Lignin modified re-tanning agents

Objective: Improving the renewability

Objective: Supporting the leather industry, tanneries, fashion, and automotive brands, with a sustainable and versatile alternative to chrome and GDA tanning.

Zeology, the sustainable tanning concept

Please swipe to view full table

Innovation is at the heart of our strategy, and we are on track to develop best-in-class chemistry. In recent years, several new patents have been registered, updates to our Product Passport have been made, and experiences have been widened with techniques like Life Cycle Assessments, wastewater guidelines, biodegradability, compostability, and circularity in general. This has led to several innovations in recent years that are currently being marketed. A selection is described below.

Develop innovative chemistry and leather-making processes to increase circularity

Please swipe to view full table

Our product range is ZDHC compliant and certified

Royal Smit & Zoon has been a contributor to the ZDHC (Zero Discharge of Hazardous Chemicals) Foundation since 2018 and strongly supports their mission to create a supply chain towards safer chemistry. In 2019, our first products were certified according to the ZDHC Conformance Level 3, and since then we included our key range in this program. Our complete product range is ZDHC compliant, whereby the % represents the volume of products certified by an independent third party. Our 2022 status is lower than the target (85%) due to an increase in new products not certified and the aftermath of Covid-19 travel limitations, restricting third-party auditing opportunities in Asia.

The basis for future compliance is our internal Restricted Substances List (RSL). This is a list of substances not present in any of our products. A steering group reviews and updates the Royal Smit & Zoon RSL annually, taking into account the following sources and criteria: Candidate List of Substances of Very High Concern (ECHA); Authorization List (Appendix XIV of REACh); List of Restrictions (Appendix XVIII of REACh); Manufacturing Restricted Substances List (MRSL of ZDHC). The Royal Smit & Zoon RSL remained unchanged, apart from changes in the official EU lists and the ZDHC MRSL version 3.0, which were, of course, included. Additionally, we are proactively phasing out unwanted substances that are not (yet) on the list of restricted substances. Substances to be phased out are selected based on their hazard and information from the market.

Here, we describe our commitments towards the environment, focusing on our ESG Roadmap 2025 commitments.

Achievements

Environment