Here, we describe our commitments towards our Social impact areas, focusing on our ESG Roadmap 2025 commitments.

Achievements

Social

Every leather product, be it a shoe, a bag, or a car seat, is made by humans. It takes many experienced workers to create the perfect leather product, from operators in a chemical plant to leather manufacturers and craftsmen in a shoe factory. As every one of these people fulfils such an important role in our business, providing a safe and healthy workplace for our employees and contractors’ employees and ensuring the safe use of our chemicals are top priorities.

Safe & Healthy workplace:

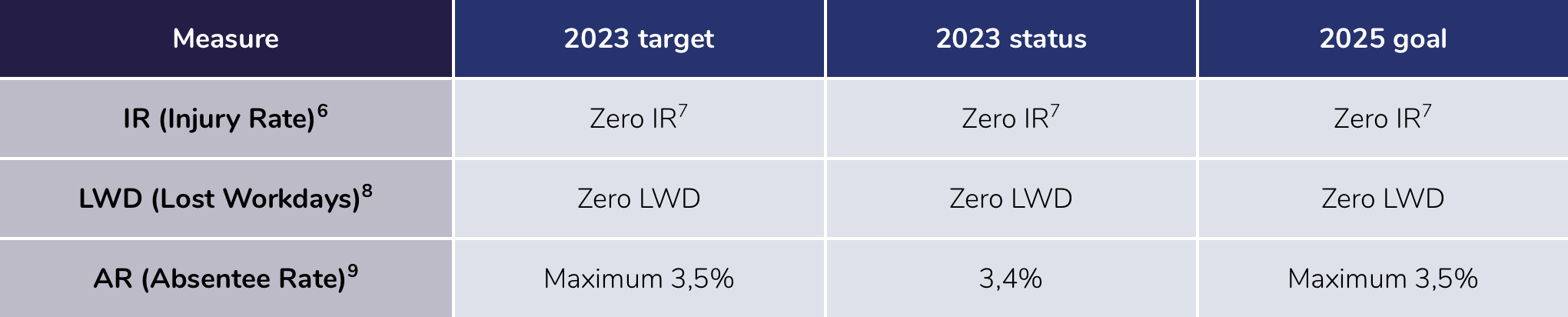

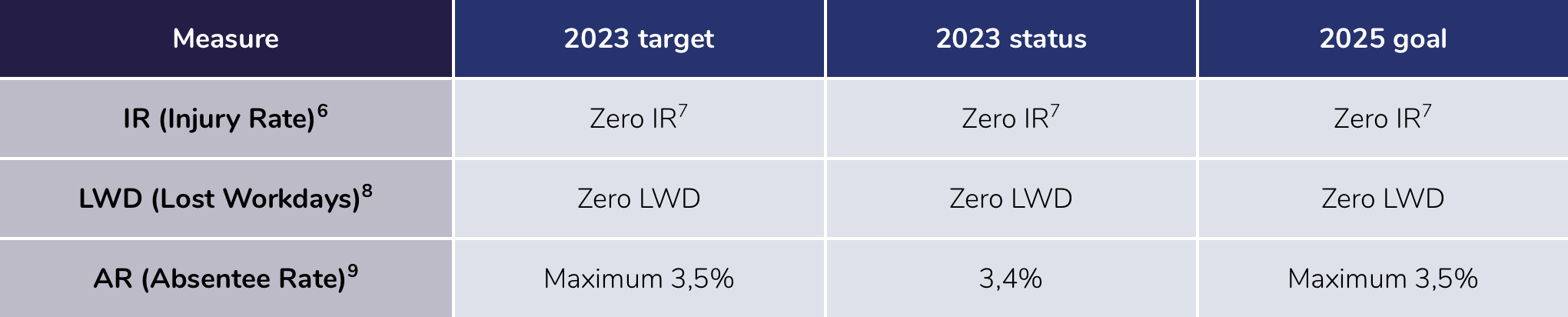

0 accidents, 0 lost working days and minimized absenteeism

We are very happy that in 2024 we had zero accidents that led to lost workdays in the whole group. This is the first time since many years that we achieved this not only in most sites, but in all sites. This is the result of year on year improving safety awareness and safe working conditions at all levels in all sites. This effort does not end here. We must and will keep improving and working on safety awareness in order to avoid accidents also in the future.

Safety & health comes first in all our activities. It is our duty to minimize the various potential risks for our employees inherent to our chemical industry operations as much as possible. The starting point is compliance with all applicable laws and regulations related to H&S at each site, with our Safety, Health & Environment Policy statement as a basis. Our Policy applies to all people working at Royal Smit & Zoon, including contractors.

Our ambition is to create an incident and injury-free work environment, with a target of zero accidents and incidents, backed by zero lost workdays and a minimal absentee rate. To build this strong safety performance across the company, we perform detailed H&S risk assessments via our internal safety risk assessment matrix. We require our employees and contractors to be trained in the appropriate safety risks and skills (defined in a training matrix for each site) and to implement world-class occupational health & safety management systems at all our sites to facilitate continuous improvement (see above KPIs). In addition, specific procedures are followed for the handling of chemicals or hazardous substances (in local languages), and protective equipment is provided to all impacted employees.

Measurement and regular audits (also by local authorities for issuing permits) are part of our continuous improvement journey. Our Operations Director (Board of Management Member) is responsible for our SHE Strategy, Policies, Standards, and Procedures. Local SHE Officers are responsible for the implementation at our premises worldwide and supporting all team members in safe working procedures. Through Works Council and/or local SHE committees, employees are consulted on local SHE developments for evaluation.

In the chapter ‘Facts & Figures’, you will find more detailed reporting on the above information and figures regarding a Safe & Healthy Workplace.

Another pivotal aspect of Health & Safety is customer health & safety, assuring the safe use of our chemicals. As a basis, we issue Safety Data Sheets with our products and implement safety instructions for our traveling team to share with downstream users. Our sales and technical teams are our ambassadors to spread this policy to our agent and distributor network as well as to our customers. Sharing our know-how and expertise with the leading industry organizations, with educational institutes in our industry, and in projects we run together with industry partners is another way to safeguard this further. Our commitment to ZDHC and eliminating restricted substances in the value chain, actively engaging and training our Sales Partners on the safe management and handling of chemicals, and promoting the Safe Use of Chemicals in Bangladesh 5, reflect our commitment to minimizing the adverse impact of our products on Health & Safety anywhere in the supply chain.

User safety is also integrated into our new product developments. In general, the Project Technical Leads in R&D work with Regulatory Affairs from the Scoping phase to start to assess compliance and safety and, where needed, already involve SHE-professionals for safety specifically. The key decision point from a safety standpoint is the ‘approval to prepare for scale up’, which means an MoC (Management of Change) needs to be written, discussed, and approved by the Plant Manager. This is the stage where SHE gets a lot more involved in ensuring Safety aspects as met.

5 Project completed in 2022, see paragraph “Promoting Safe Use of Chemicals”

6 Number of Lost Time Injuries per 200.000 worked hours

7 For employees and contractors

8 Number of Lost Working Days per 200.000 worked hours

9 Percentage of sick days over worked days

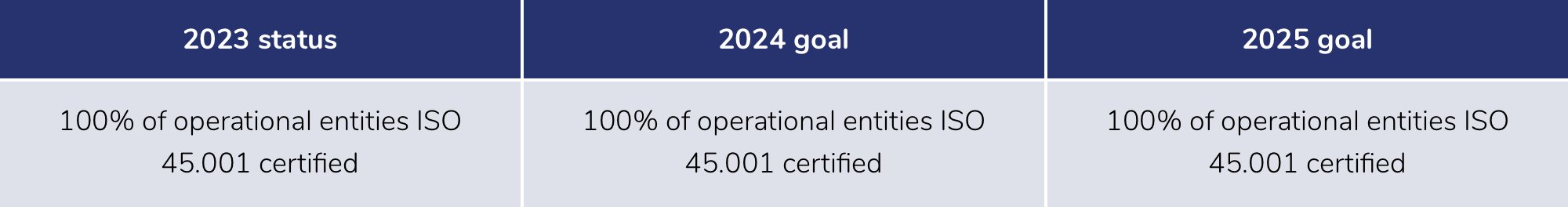

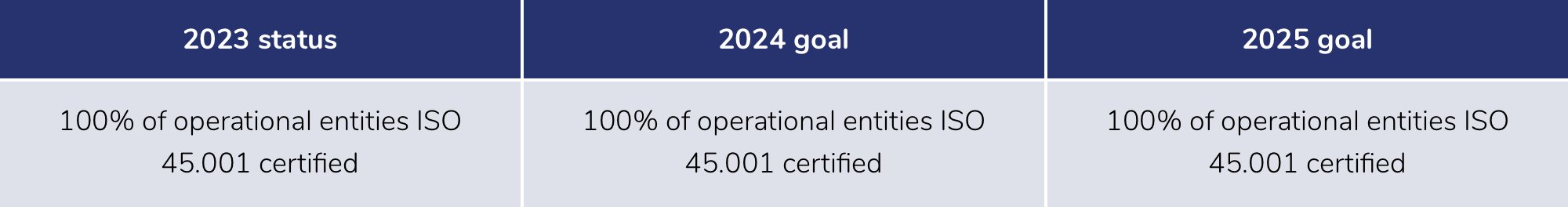

Already in 2022, our final production entity in India obtained ISO 45.001 certification. Based on this reputable certification, this means all our entities have world-class social management systems in place. Royal Smit & Zoon views the implementation of its social management system as a process of continuous improvement. According to the Plan-Do-Check-Act Cycle, the ISO 45.001 certification requires ongoing review of our practices, processes, and procedures, periodic internal and external audits to verify and check, and, where needed – improved implementation.

All entities have world class occupational health and safety management systems in place

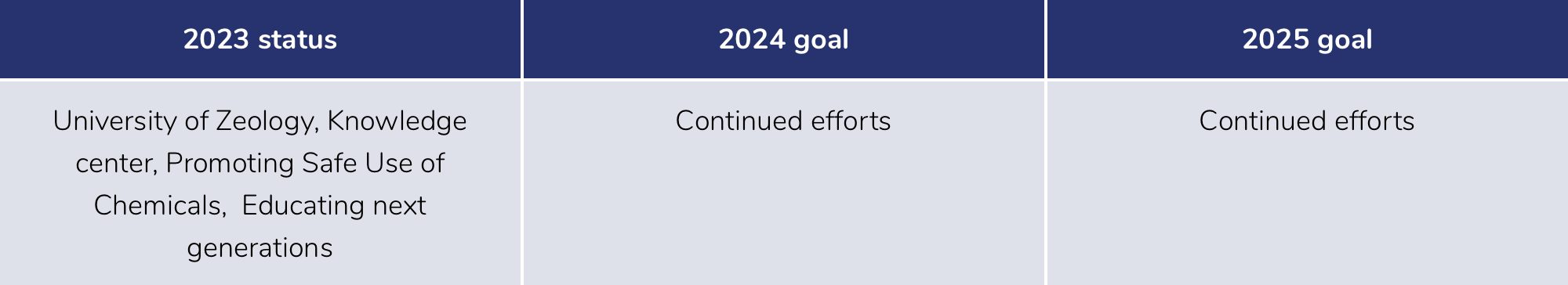

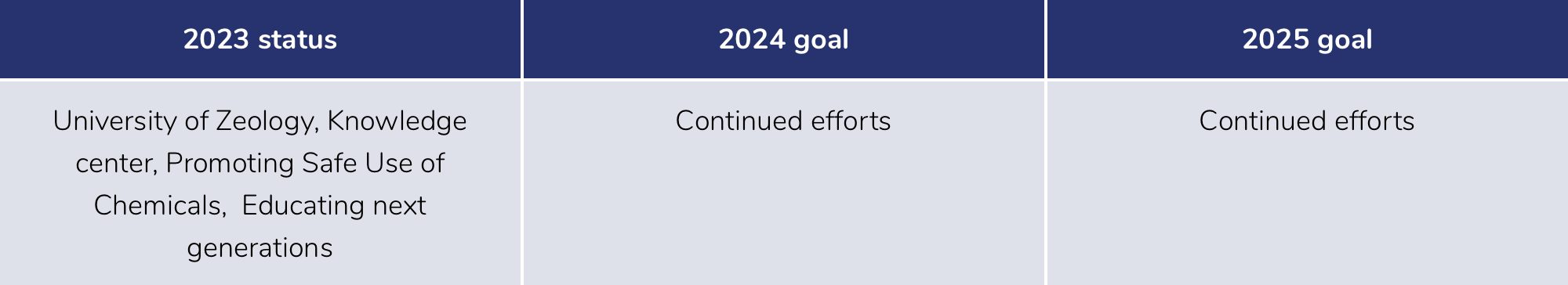

Education and community involvement are important to demonstrate our thought leadership. We intend to continue taking initiatives building further on the below topics.

Ongoing efforts in education and community involvement, to demonstrate thought leadership

University of Zeology

The University of Zeology provides in-depth and transparent information relating to Zeology and other relevant insight topics like the leather manufacturing process, waste streams, and biodegradability. Besides sharing knowledge, the University of Zeology is also a web section where our opinion on hot topics, such as compostability and the transformation from a linear process to a circular process, can be found.

Knowledge center

Knowledge is an incredibly powerful tool and, at Royal Smit & Zoon, we are convinced that it is more powerful when it is shared. Sharing enables people to learn, grow, and make informed decisions. It also opens up new ways of thinking and brings opportunities. We think being transparent and sharing our knowledge, especially with our customers, will improve their user experience and often lead to innovation. Bringing different perspectives and ideas together sparks creativity and brings new solutions to existing problems. We share our knowledge on SmitZoon.com at a dedicated section where we want people to stay curious, seek for new information and adapt to changing circumstances. We are firm believers that sharing knowledge creates a ripple effect of positive impact across individuals, communities, and society.

Promoting Safe Use of Chemicals

Being a chemical manufacturer, we consider the safe use of chemicals an absolute priority topic. Royal Smit & Zoon has been involved in various training efforts and in creating models like the advanced Leather Working Group Protocol 7.2 to promote the safe use of chemicals. Until 2022, we have we have been involved in a 3-year training program in Bangladesh on ‘Promoting Safe Use of Chemicals’ (PSUC), in collaboration with TEGEWA. The final training reached over 3,700 leather industry employees (worker and floor level) and showed them how to work safely with chemicals. On our website, you can download the safety guidelines in various languages. Since the program concluded in 2022, we have engaged with civil society organization Solidaridad to explore extending the training program’s insights to additional countries. In addition to our training program for Sales Partners, our goal is to continue contributing to the promotion of the safe use of chemicals among a broader industry audience.

Next Generations

Royal Smit & Zoon is supporting the development of the next generations of leather technicians. This is done in multiple ways: supporting education within the leather industry and hiring young leather technicians. In 2023, Royal Smit & Zoon continued to be involved in training and traineeships. As an illustration, we conducted a 2-day training to students in China covering the safe management and handling of chemicals, as well as how to make leather. This finishing workshop benefitted 45 students at Shaanxi University and 16 students at Jiaxing University, whereby each of them was granted a certificate for completion. In Brazil, we organised a dedicated week inside the National Service for Industrial Training (SENAI) in partnership with our local Sales Partner Quimica Carioca, focusing on the training and development of (future) leather technicians. During the first week of December, 80 students underwent training and performed a total of 32 leather-making trials. In leather educational institutions, we collaborate with ICLT in the UK, with ITECH in France, with FILK Freiburg Insititute in Germany and with CLRI in India.

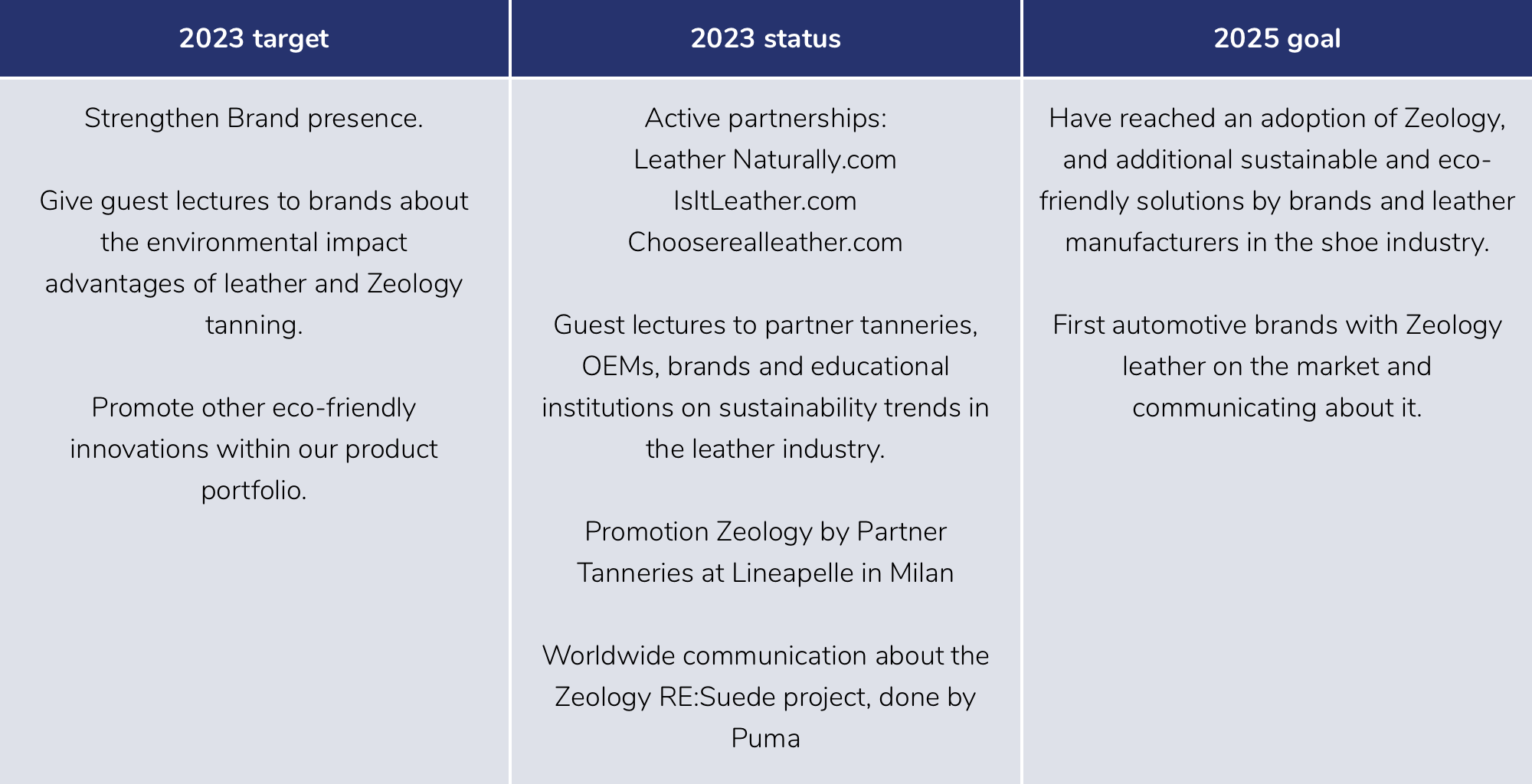

Royal Smit & Zoon is a member of Leather Naturally, which is focusing on education and the promotion of leather to brands, designers, and consumers. During 2023, we supported social media campaigns “#isitleather” and “#chooserealleather”. Both advocate for natural leather by informing and educating consumers, enabling transparency, and ending confusion regarding fake leather alternative products.

In 2023, we actively supported responsible material decision-making, recognizing leather as an upcycled material with unique, sustainable characteristics.

We are actively involved in consumer and brand communication

10 https://doi.org/10.4060/cc7474en

11 Leather Car Interiors Are Benefitting The Planet - One 4 Leather

Guest lectures

In 2023, the Food and Agriculture Organization of the United Nations (FAO) released a report 10 on sustainable livestock transformation highlighting that “The world population is projected to reach 9.8 billion in 2050. In tandem with this population growth, the demand for milk, meat and eggs is projected to increase by more than 20 percent between 2020 and 2050.” Consequently, a parallel increase in the supply of hides is anticipated. Aligned with these projections, approximately 40% of all hides still end up in landfill as indicated in the report “Leather car interiors are benefitting the Planet” by One4Leather 11. Turning hides, that are a by-product of the meat industry, into leather is not only producing a sustainable and durable material, but also prevents these hides to end up as waste (and release their captured CO2). Leather thereby contributes to a more sustainable food system and a circular economy.

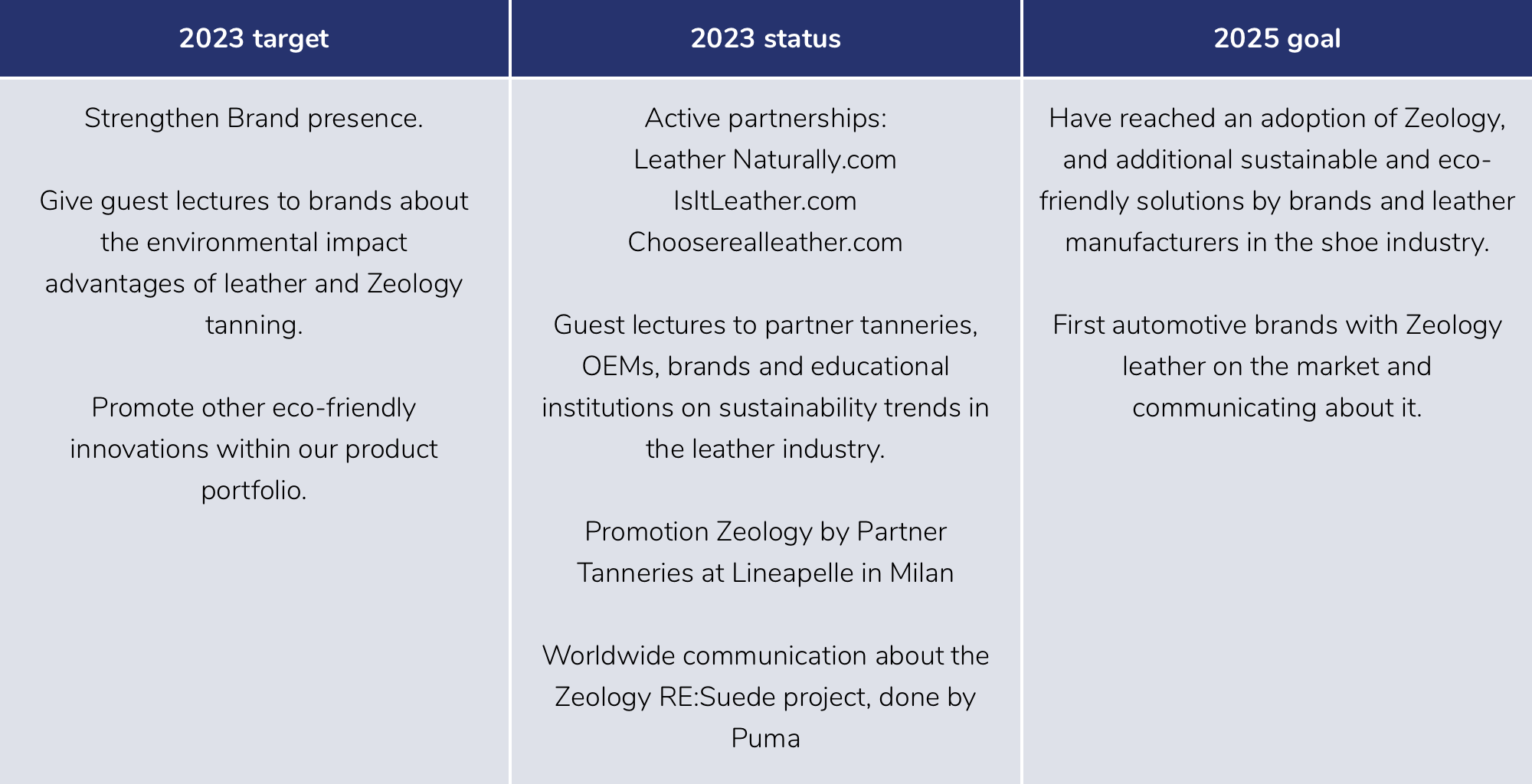

Recognizing this challenge, Royal Smit & Zoon invests significant resources in taking along and educating partner tanneries, OEMs, brands and educational institutions. During guest lectures, we share knowledge on sustainability trends in the leather industry, educate on the chemistry of leather and application of leather as opposed to synthetic alternatives. Accordingly, in 2023, we gave guest lectures to 27 partner tanneries, 59 brands and 7 educational institutions. In addition, we hosted two online sessions for brands and civil society organizations at The Sustainable Academy, educating about leather in general and different tanning methods.

ZeologyLeather.com

We launched a consumer-oriented website in 2023 focused on providing validated information about leather, valuable resources and assistance to the consumer. We regularly analyse user data and feedback to understand our audience better and further tailor our website to meet their needs effectively.

Zeology Tanneries

We optimized our interactive and informative webpage for brands and designers, where they can easily navigate their way to the nearest Zeology tannery. We want to enable the visitor to select the tannery, not only per region but also on product choice. This is an important step toward servicing our customers better. This optimized webpage also gives our partner tanneries a great platform to profile their business as being part of the Zeology network and to acquire new leads. Eight partner tanneries promoted Zeology leather at Lineapelle Leather Fair in Milan. The number of tanneries promoting Zeology totalled 28 by the end of 2023.

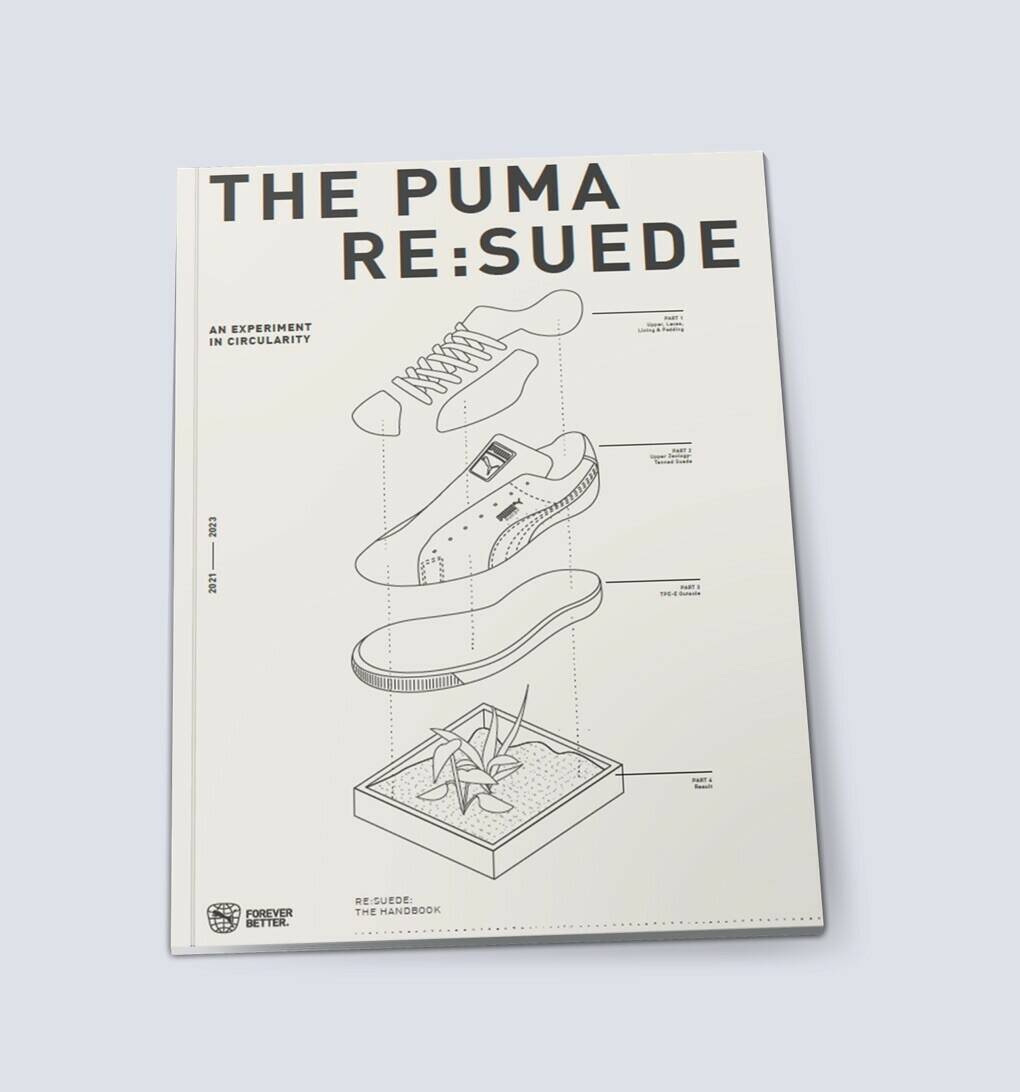

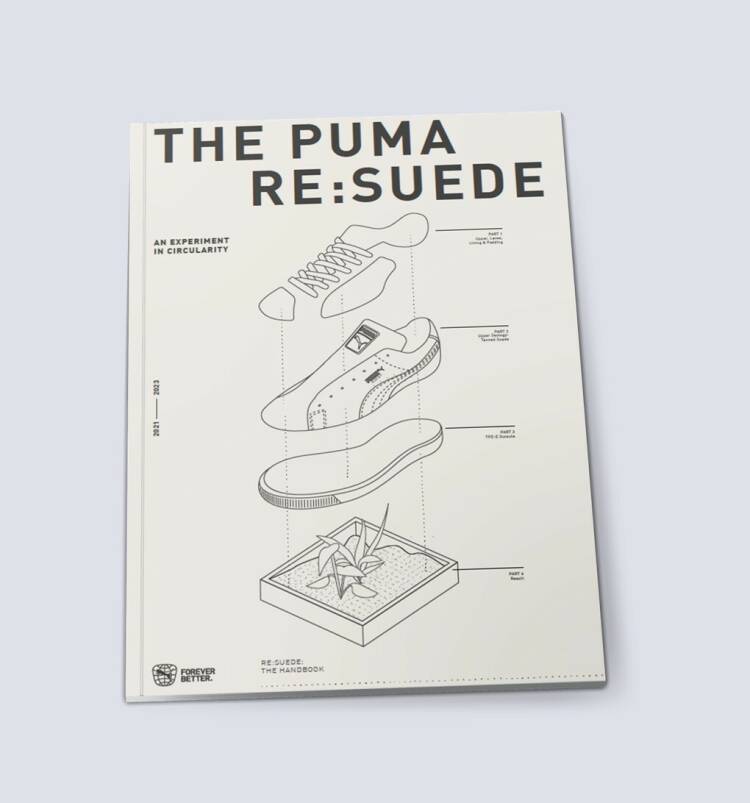

Zeology RE-Suede Project, done by Puma

When Puma introduced their 10FOR25 sustainability targets, they made circularity one of their focus areas. In 2021 they started “Circular Lab”, an innovation hub, which is led by their innovation and design experts. The first project to come out of “Circular Lab” was RE:SUEDE, a trial for a shoe that can turn into compost. We collaborated in this pilot with Puma to test the first fully compostable shoes. So far, only Zeology-tanned leather fulfils the industrial compost requirements and allows game-changing thinking and production in the shoe industry worldwide. The RE:SUEDE shoe is an important first step in shaping a circular future.

Could we make a shoe designed for composting that people would want to wear?

Would people go to the effort of returning their shoes after they’d been worn?

Would we be able to successfully turn the shoe into compost after it had been worn?

If the experiment were a success, how feasible would it be to scale up?

Overall, 500 people took part in the experiment and enjoyed wearing their RE:Suede’s.

In total 88% wore their RE:suede shoes 2-3 times per week for everyday occasions. And 68% said they would recommend the sneakers to friends, family or colleagues in the future.

But there is still work to do to make the RE:Suede as comfortable as the original because 57% found the shoes uncomfortable, with lack of cushioning and fit as the top reasons.

Regarding compostability, they discovered that it is possible to turn the RE:SUEDE into Grade A compost under specific industrial conditions provided (by Ortessa). That’s a huge win! Puma published all the results of the RE:Suede pilot in their handbook.

Royal Smit & Zoon team members are also actively involved in wider stakeholder and community discussions (LinkedIn, platforms, private networks), and we frequently invite brands and designers to our premises to show the beauty and sustainability of leather.

For Puma, RE:SUEDE is more than just a shoe: it’s an experiment in circularity. Through this experiment, they set out to find answers to some important questions:

UN SDG goals

We addressed UN SDGs 6, 8, 12, and 17, and a series of Materiality Matrix topics, including Occupational Health & Safety, Human Rights & labor practices, Talent attraction, retention & development, Product stewardship, Community management & engagement, Sustainable product innovations & Circularity.

The Koornzaayer Foundation aims to initiate sustainable change and carries out these activities with the Sustainable Development Goals (SDGs) in mind.

We aim to contribute to a society where every individual can lead a dignified life. We view equal access to education as the fundamental catalyst empowering people to shape their own future. With this mission in mind, Joost Smit, the 6th generation owner of Royal Smit & Zoon, set up the Koornzaayer Foundation. The foundation - named after the ship our founder Albert Smit was the captain of in 1821 - supports (local) organisations on to provide education and access to water in Kenya and Uganda.

The Koornzaayer Foundation

Focus 2023 - 2028

In recent years, the focus has shifted from healthcare and providing access to water to education, based on the belief that education provides people with the key ingredient to a better future.

As a foundation that has its roots in the Netherlands, the Koornzaayer Foundation also supports education projects locally. The board has the ambition to expand the foundation’s activities in the Netherlands over the coming years.

Kenya

Victoria Friendly Montessori

The Koornzaayer Foundation works since 2014 with Victoria Friendly Montessori (VFM) in Kenia. VFM is a local organisation that focuses on developing capacities among grassroots communities along Lake Victoria. It seeks to mitigate the effects of poverty through sustainable community-led interventions. Through their social services, VFM runs several programs, among which are child protection and skilful parenting. These programmes are committed to changing livelihoods on Rusinga Island in collaboration with different stakeholders.

100 WEEKS Program on Rusinga Island

This year we started a two-year program with 100 WEEKS for 100 women on Rusinga Island. 100 WEEKS created a new, revolutionary way of providing help. By immediately giving a small amount to the poorest women, they will permanently escape extreme poverty within 100 weeks.

The Netherlands

IMC Weekend School

The Koornzaayer Foundation started a new partnership with the IMC Weekend School this year.

Overall, 500 people took part in the experiment and enjoyed wearing their RE:Suede’s.

In total 88% wore their RE:suede shoes 2-3 times per week for everyday occasions. And 68% said they would recommend the sneakers to friends, family or colleagues in the future.

But there is still work to do to make the RE:Suede as comfortable as the original because 57% found the shoes uncomfortable, with lack of cushioning and fit as the top reasons.

Regarding compostability, they discovered that it is possible to turn the RE:SUEDE into Grade A compost under specific industrial conditions provided (by Ortessa). That’s a huge win! Puma published all the results of the RE:Suede pilot in their handbook.

Royal Smit & Zoon team members are also actively involved in wider stakeholder and community discussions (LinkedIn, platforms, private networks), and we frequently invite brands and designers to our premises to show the beauty and sustainability of leather.

Could we make a shoe designed for composting that people would want to wear?

Would people go to the effort of returning their shoes after they’d been worn?

Would we be able to successfully turn the shoe into compost after it had been worn?

If the experiment were a success, how feasible would it be to scale up?

For Puma, RE:SUEDE is more than just a shoe: it’s an experiment in circularity. Through this experiment, they set out to find answers to some important questions:

Zeology RE-Suede Project, done by Puma

When Puma introduced their 10FOR25 sustainability targets, they made circularity one of their focus areas. In 2021 they started “Circular Lab”, an innovation hub, which is led by their innovation and design experts. The first project to come out of “Circular Lab” was RE:SUEDE, a trial for a shoe that can turn into compost. We collaborated in this pilot with Puma to test the first fully compostable shoes. So far, only Zeology-tanned leather fulfils the industrial compost requirements and allows game-changing thinking and production in the shoe industry worldwide. The RE:SUEDE shoe is an important first step in shaping a circular future.

Promoting Safe Use of Chemicals

Being a chemical manufacturer, we consider the safe use of chemicals an absolute priority topic. Royal Smit & Zoon has been involved in various training efforts and in creating models like the advanced Leather Working Group Protocol 7.2 to promote the safe use of chemicals. Until 2022, we have we have been involved in a 3-year training program in Bangladesh on ‘Promoting Safe Use of Chemicals’ (PSUC), in collaboration with TEGEWA. The final training reached over 3,700 leather industry employees (worker and floor level) and showed them how to work safely with chemicals. On our website, you can download the safety guidelines in various languages. Since the program concluded in 2022, we have engaged with civil society organization Solidaridad to explore extending the training program’s insights to additional countries. In addition to our training program for Sales Partners, our goal is to continue contributing to the promotion of the safe use of chemicals among a broader industry audience.

Every leather product, be it a shoe, a bag, or a car seat, is made by humans. It takes many experienced workers to create the perfect leather product, from operators in a chemical plant to leather manufacturers and craftsmen in a shoe factory. As every one of these people fulfils such an important role in our business, providing a safe and healthy workplace for our employees and contractors’ employees and ensuring the safe use of our chemicals are top priorities.

Please swipe to view full table

Already in 2022, our final production entity in India obtained ISO 45.001 certification. Based on this reputable certification, this means all our entities have world-class social management systems in place. Royal Smit & Zoon views the implementation of its social management system as a process of continuous improvement. According to the Plan-Do-Check-Act Cycle, the ISO 45.001 certification requires ongoing review of our practices, processes, and procedures, periodic internal and external audits to verify and check, and, where needed – improved implementation.

All entities have world class occupational health and safety management systems in place

The Netherlands

IMC Weekendschool provides extracurricular education to children, aged 10-14, from underprivileged neighbourhoods. Through their programs students are provided with the skills, knowledge and audacity that are needed to find a place in society that matches their capacities. The contacts created between passionate professionals and students bridge social inequalities and affect both parties. In an alumni program, guest teachers, sponsors and alumni stay connected, and develop professional relationships.

IMC Weekend School

The Koornzaayer Foundation started a new partnership with the IMC Weekend School this year.

100 WEEKS Program on Rusinga Island

Weekly Village Savings and Loans Associations (VSLA) meetings: All participants come together on a weekly basis in the VSLA’s to save, take out & pay back loans, and contribute to a solidarity fund. 100WEEKS regularly monitored the VSLA’s to check whether correct procedures were followed.

Weekly training: All participants receive training from 100WEEKS in empowerment, financial literacy entrepreneurial skills and life skills.

Weekly cash transfers: all participants receive each Monday morning €8 on their mobile phones over the course of 100 weeks. They can invest in their families, business or community as they see fit.

The 100 WEEKS CASH+ Program consists of three mutually reinforcing components.

This year we started a two-year program with 100 WEEKS for 100 women on Rusinga Island. 100 WEEKS created a new, revolutionary way of providing help. By immediately giving a small amount to the poorest women, they will permanently escape extreme poverty within 100 weeks.

Kenya

Victoria Friendly Montessori

The Koornzaayer Foundation works since 2014 with Victoria Friendly Montessori (VFM) in Kenia. VFM is a local organisation that focuses on developing capacities among grassroots communities along Lake Victoria. It seeks to mitigate the effects of poverty through sustainable community-led interventions. Through their social services, VFM runs several programs, among which are child protection and skilful parenting. These programmes are committed to changing livelihoods on Rusinga Island in collaboration with different stakeholders.

We are very happy to report that in 2023 the water started running at Rusinga. Water is abstracted from Lake Victoria and pumped uphill by solar to a 214 cubic meters’ tank. Water is then distributed to households by gravity through different distribution pipelines. Four community water points fitted with digital water meters are standing to provide water to families who are not privately connected. Forty households have been connected privately since its completion in mid-November and clean water flowing in their taps. Consequently, 321 people are benefiting from the communal water points.

From 2024 onwards, the model will be scaled up and the number of connected homes will be increased. The end goal is to provide the whole 35.000 people with access to healthy water for their hygiene and for irrigation. This way, we can improve food security, the diversification of income sources, and, not unimportantly, we hope to combat erosion on the island.

In 2022, the research for options of getting water connections on the island was concluded, and our local partners discussed the outcome with the local government, the community, and all others that needed to be involved. Based on the research results and outcome of discussions, it was decided to work with a local party that can install and manage a water distribution system, home connections, and water meters at each home. At the end of 2022, we started the model on a small scale by constructing the full system for several homes.

In our previous reports, we mentioned Koornzaayer Foundation’s joint interest in further improving the effectiveness of food security together with VOx Impuls. The defined focus is on securing access to safe and sustainable water sources that are manageable by the communities themselves, being a crucial means for food security.

Focus 2023 - 2028

In recent years, the focus has shifted from healthcare and providing access to water to education, based on the belief that education provides people with the key ingredient to a better future.

As a foundation that has its roots in the Netherlands, the Koornzaayer Foundation also supports education projects locally. The board has the ambition to expand the foundation’s activities in the Netherlands over the coming years.

The Koornzaayer Foundation aims to initiate sustainable change and carries out these activities with the Sustainable Development Goals (SDGs) in mind.

We aim to contribute to a society where every individual can lead a dignified life. We view equal access to education as the fundamental catalyst empowering people to shape their own future. With this mission in mind, Joost Smit, the 6th generation owner of Royal Smit & Zoon, set up the Koornzaayer Foundation. The foundation - named after the ship our founder Albert Smit was the captain of in 1821 - supports (local) organisations on to provide education and access to water in Kenya and Uganda.

The Koornzaayer Foundation

Zeology Tanneries

We optimized our interactive and informative webpage for brands and designers, where they can easily navigate their way to the nearest Zeology tannery. We want to enable the visitor to select the tannery, not only per region but also on product choice. This is an important step toward servicing our customers better. This optimized webpage also gives our partner tanneries a great platform to profile their business as being part of the Zeology network and to acquire new leads. Eight partner tanneries promoted Zeology leather at Lineapelle Leather Fair in Milan. The number of tanneries promoting Zeology totalled 28 by the end of 2023.

ZeologyLeather.com

We launched a consumer-oriented website in 2023 focused on providing validated information about leather, valuable resources and assistance to the consumer. We regularly analyse user data and feedback to understand our audience better and further tailor our website to meet their needs effectively.

UN SDG goals

We addressed UN SDGs 6, 8, 12, and 17, and a series of Materiality Matrix topics, including Occupational Health & Safety, Human Rights & labor practices, Talent attraction, retention & development, Product stewardship, Community management & engagement, Sustainable product innovations & Circularity.

10 https://doi.org/10.4060/cc7474en

11 Leather Car Interiors Are Benefitting The Planet - One 4 Leather

Guest lectures

In 2023, the Food and Agriculture Organization of the United Nations (FAO) released a report 10 on sustainable livestock transformation highlighting that “The world population is projected to reach 9.8 billion in 2050. In tandem with this population growth, the demand for milk, meat and eggs is projected to increase by more than 20 percent between 2020 and 2050.” Consequently, a parallel increase in the supply of hides is anticipated. Aligned with these projections, approximately 40% of all hides still end up in landfill as indicated in the report “Leather car interiors are benefitting the Planet” by One4Leather 11. Turning hides, that are a by-product of the meat industry, into leather is not only producing a sustainable and durable material, but also prevents these hides to end up as waste (and release their captured CO2). Leather thereby contributes to a more sustainable food system and a circular economy.

Recognizing this challenge, Royal Smit & Zoon invests significant resources in taking along and educating partner tanneries, OEMs, brands and educational institutions. During guest lectures, we share knowledge on sustainability trends in the leather industry, educate on the chemistry of leather and application of leather as opposed to synthetic alternatives. Accordingly, in 2023, we gave guest lectures to 27 partner tanneries, 59 brands and 7 educational institutions. In addition, we hosted two online sessions for brands and civil society organizations at The Sustainable Academy, educating about leather in general and different tanning methods.

Please swipe to view full table

Royal Smit & Zoon is a member of Leather Naturally, which is focusing on education and the promotion of leather to brands, designers, and consumers. During 2023, we supported social media campaigns “#isitleather” and “#chooserealleather”. Both advocate for natural leather by informing and educating consumers, enabling transparency, and ending confusion regarding fake leather alternative products.

In 2023, we actively supported responsible material decision-making, recognizing leather as an upcycled material with unique, sustainable characteristics.

We are actively involved in consumer and brand communication

Next Generations

Royal Smit & Zoon is supporting the development of the next generations of leather technicians. This is done in multiple ways: supporting education within the leather industry and hiring young leather technicians. In 2023, Royal Smit & Zoon continued to be involved in training and traineeships. As an illustration, we conducted a 2-day training to students in China covering the safe management and handling of chemicals, as well as how to make leather. This finishing workshop benefitted 45 students at Shaanxi University and 16 students at Jiaxing University, whereby each of them was granted a certificate for completion. In Brazil, we organised a dedicated week inside the National Service for Industrial Training (SENAI) in partnership with our local Sales Partner Quimica Carioca, focusing on the training and development of (future) leather technicians. During the first week of December, 80 students underwent training and performed a total of 32 leather-making trials. In leather educational institutions, we collaborate with ICLT in the UK, with ITECH in France, with FILK Freiburg Insititute in Germany and with CLRI in India.

Knowledge center

Knowledge is an incredibly powerful tool and, at Royal Smit & Zoon, we are convinced that it is more powerful when it is shared. Sharing enables people to learn, grow, and make informed decisions. It also opens up new ways of thinking and brings opportunities. We think being transparent and sharing our knowledge, especially with our customers, will improve their user experience and often lead to innovation. Bringing different perspectives and ideas together sparks creativity and brings new solutions to existing problems. We share our knowledge on SmitZoon.com at a dedicated section where we want people to stay curious, seek for new information and adapt to changing circumstances. We are firm believers that sharing knowledge creates a ripple effect of positive impact across individuals, communities, and society.

University of Zeology

The University of Zeology provides in-depth and transparent information relating to Zeology and other relevant insight topics like the leather manufacturing process, waste streams, and biodegradability. Besides sharing knowledge, the University of Zeology is also a web section where our opinion on hot topics, such as compostability and the transformation from a linear process to a circular process, can be found.

Please swipe to view full table

Education and community involvement are important to demonstrate our thought leadership. We intend to continue taking initiatives building further on the below topics.

Ongoing efforts in education and community involvement, to demonstrate thought leadership

5 Project completed in 2022, see paragraph “Promoting Safe Use of Chemicals”

6 Number of Lost Time Injuries per 200.000 worked hours

7 For employees and contractors

8 Number of Lost Working Days per 200.000 worked hours

9 Percentage of sick days over worked days

Please swipe to view full table

Safe & Healthy workplace:

0 accidents, 0 lost working days and minimized absenteeism

We are very happy that in 2024 we had zero accidents that led to lost workdays in the whole group. This is the first time since many years that we achieved this not only in most sites, but in all sites. This is the result of year on year improving safety awareness and safe working conditions at all levels in all sites. This effort does not end here. We must and will keep improving and working on safety awareness in order to avoid accidents also in the future.

Safety & health comes first in all our activities. It is our duty to minimize the various potential risks for our employees inherent to our chemical industry operations as much as possible. The starting point is compliance with all applicable laws and regulations related to H&S at each site, with our Safety, Health & Environment Policy statement as a basis. Our Policy applies to all people working at Royal Smit & Zoon, including contractors.

Our ambition is to create an incident and injury-free work environment, with a target of zero accidents and incidents, backed by zero lost workdays and a minimal absentee rate. To build this strong safety performance across the company, we perform detailed H&S risk assessments via our internal safety risk assessment matrix. We require our employees and contractors to be trained in the appropriate safety risks and skills (defined in a training matrix for each site) and to implement world-class occupational health & safety management systems at all our sites to facilitate continuous improvement (see above KPIs). In addition, specific procedures are followed for the handling of chemicals or hazardous substances (in local languages), and protective equipment is provided to all impacted employees.

Measurement and regular audits (also by local authorities for issuing permits) are part of our continuous improvement journey. Our Operations Director (Board of Management Member) is responsible for our SHE Strategy, Policies, Standards, and Procedures. Local SHE Officers are responsible for the implementation at our premises worldwide and supporting all team members in safe working procedures. Through Works Council and/or local SHE committees, employees are consulted on local SHE developments for evaluation.

In the chapter ‘Facts & Figures’, you will find more detailed reporting on the above information and figures regarding a Safe & Healthy Workplace.

Another pivotal aspect of Health & Safety is customer health & safety, assuring the safe use of our chemicals. As a basis, we issue Safety Data Sheets with our products and implement safety instructions for our traveling team to share with downstream users. Our sales and technical teams are our ambassadors to spread this policy to our agent and distributor network as well as to our customers. Sharing our know-how and expertise with the leading industry organizations, with educational institutes in our industry, and in projects we run together with industry partners is another way to safeguard this further. Our commitment to ZDHC and eliminating restricted substances in the value chain, actively engaging and training our Sales Partners on the safe management and handling of chemicals, and promoting the Safe Use of Chemicals in Bangladesh 5, reflect our commitment to minimizing the adverse impact of our products on Health & Safety anywhere in the supply chain.

User safety is also integrated into our new product developments. In general, the Project Technical Leads in R&D work with Regulatory Affairs from the Scoping phase to start to assess compliance and safety and, where needed, already involve SHE-professionals for safety specifically. The key decision point from a safety standpoint is the ‘approval to prepare for scale up’, which means an MoC (Management of Change) needs to be written, discussed, and approved by the Plant Manager. This is the stage where SHE gets a lot more involved in ensuring Safety aspects as met.

Here, we describe our commitments towards our Social impact areas, focusing on our ESG Roadmap 2025 commitments.

Achievements

Social