Here, we describe our commitments towards the environment, focusing on our ESG Roadmap 2025 commitments.

Achievements

Environment

Our product range is ZDHC compliant and certified

Royal Smit & Zoon has been an active contributor to the ZDHC (Zero Discharge of Hazardous Chemicals) Foundation since 2018. Our Partnership acknowledges our joint commitment to uphold the highest environmental and social responsibility standards throughout our operations. Our product development strictly adheres to the ZDHC specifications and reflects our dedication to sustainable chemical management.

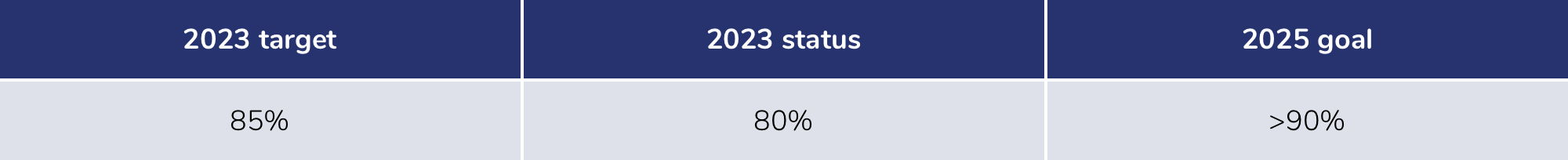

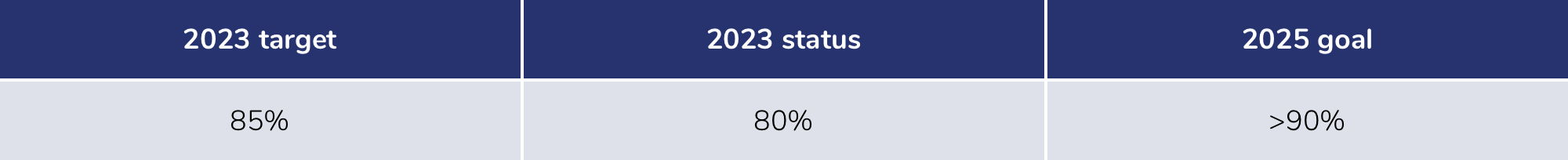

Already in 2019, our key product range was certified according to the ZDHC Conformance Level 3. In 2023, our certificates were renewed through the bi-annual process and fully available on our website. Our annual performance is mostly unchanged and remains slightly below the 2023 target of 85%. This outcome is attributed to market developments experienced over the past couple of years, the pending certification of new products, and the current absence of certification of our production site in India. In response, efforts are underway to prepare our Indian site for certification in 2024 and align excellence across our factories worldwide.

Due to tighter regulations and customer requests, Royal Smit & Zoon expanded its own Manufacturing Restricted Substance List (MRSL) considering the ZDHC MRSL, the Candidate List of Substances of Very High Concern (SVHC), the Authorization List

(REACh Appendix XIV), and the Restrictions List (REACh Appendix XVIII). This ultimately means substances are banned from being intentionally used during the manufacturing process. Our MRSL is updated at least once a year. Furthermore, we are voluntarily phasing out unwanted substances not (yet) on the list of restricted substances. This decision is based on the substance hazards, market information, or ESG ambitions and regulatory insights. Through these initiatives, we actively contribute to a more sustainable and responsible chemical management in our supply chain.

% based on volume sold

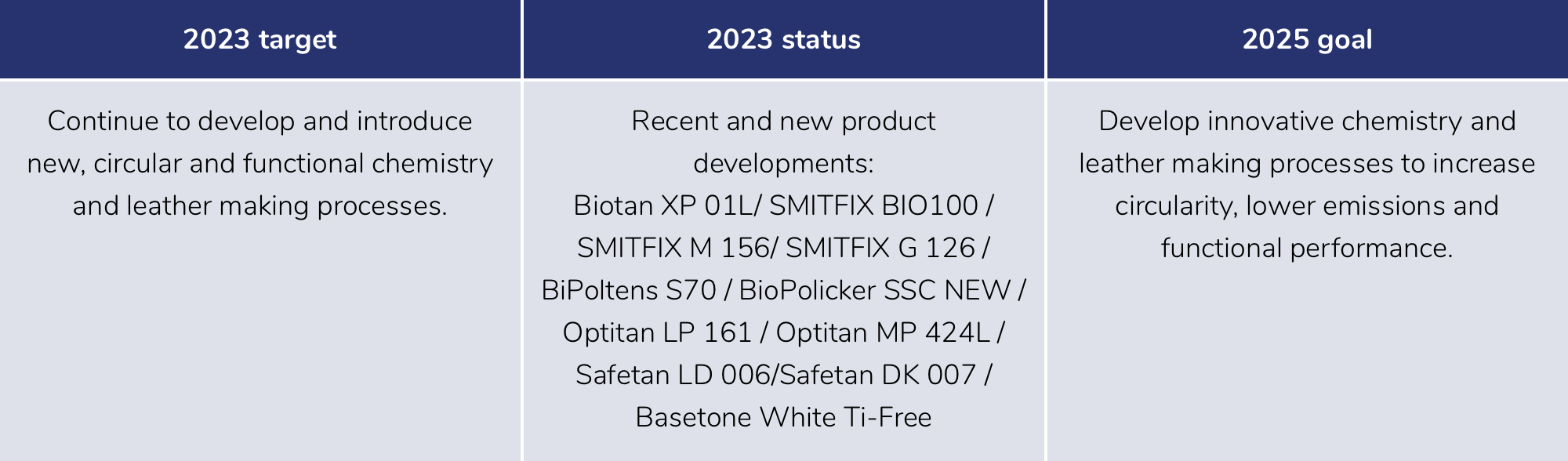

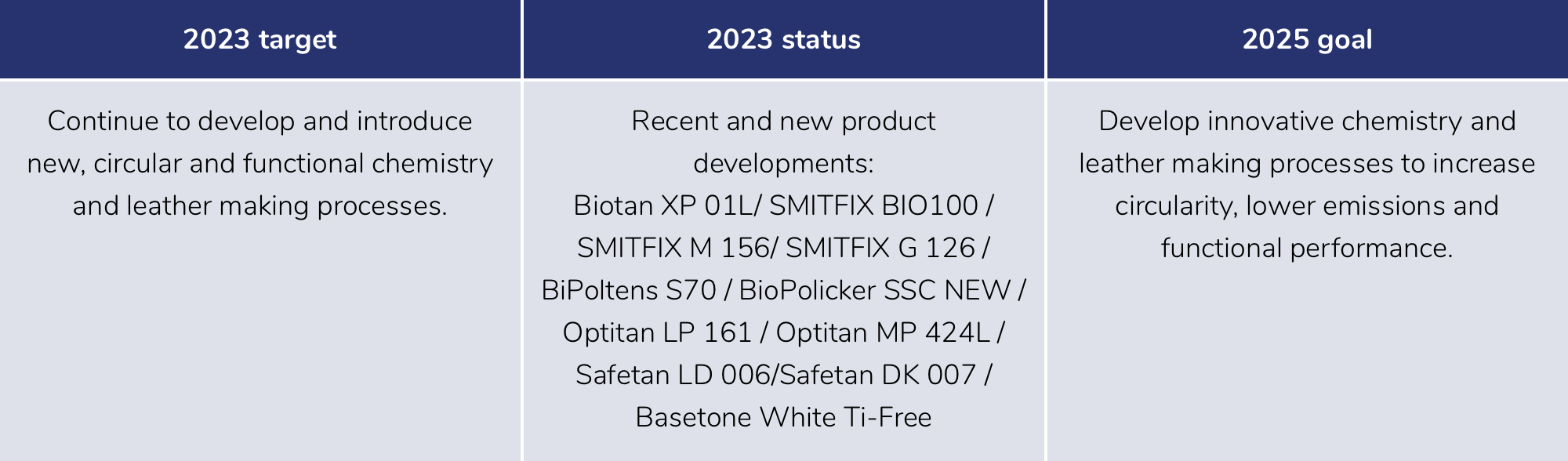

Innovation is at the heart of our strategy, and we are on track to develop best-in-class chemistry. In recent years, several new patents have been registered, updates to our Product Passport have been made, and experiences have been widened with techniques like Life Cycle Assessments, wastewater guidelines, biodegradability, compostability, and circularity in general. This has led to several innovations in recent years that are currently being marketed. A selection is described below.

Develop innovative chemistry and leather-making processes to increase circularity

In 2023, Zeology, the chrome, heavy metal and aldehyde free tanning agent based on modified zeolite, has experienced a further adoption. We witnessed a significant increase in the number of tanneries producing leather with Zeology, an increased number of leather producers offering Zeology leather to brands and Original Equipment Manufacturers (OEMs) and Zeology leather being presented at fairs or via their online channels (e.g., Puma; Tasman Tanning; Emma Safety Footwear; Ted Louise; Nuova ECOS; Vicenza Pelli). In addition, we saw an increasing demand from brands and OEMs requesting specifically for Zeology leather. In 2024, we anticipate the first car brands to launch Zeology tanned automotive leather in their vehicles. With this, Zeology is increasingly driving significant impact in making the leather value chain more sustainable. You can find more information on brand engagement under ‘Social’.

While the adoption of Zeology is progressing well, the landscape of leather tanning is undergoing rapid and transformative changes. As the demand for chrome free leather continues to grow, the European Chemicals Agency (ECHA) has increased legislative pressure on the traditional chrome free tanning agent GDA (also referenced to as glutardialdehyde or glutaral). ECHA recommended 4 the inclusion of GDA as a substance in Annex XIV of REACH (List of Substances subject to Authorisation), signalling expected restrictions on the production and application of the listed substances. By providing a sustainable solution as Zeology, we support tanneries, brands and OEMs in meeting market demands and anticipating upcoming legislations.

We understand that responsible procurement of raw materials is a crucial part of building a sustainable supply chain. This is why the alumina trihydrate (ATH) used to produce the zeolite for our tanning product Zeology meets the highest ESG standards and has been certified according to the Aluminium Stewardship Initiative (ASI) standards since 2022. This way Nera guarantees that all steps in our value chain from the bauxite mining until and including the production of zeolite comply with the ASI Performance Standard and the ASI Chain of Custody Standard. ASI standards address various ESG topics such as environmental impact, material stewardship, human and labour rights, and business governance. Next to working with zeolite from certified ATH, Nera has become a supporting member of the Aluminium Stewardship Initiative in 2023.

Sharing knowledge and evidence for our claims and being transparent are crucial aspects. For that reason, Royal Smit & Zoon/Nera focused on sharing information through our websites, whitepapers, organizing Masterclasses, and obtaining certifications proving Zeology is a sustainable solution. Besides ESG related certifications such as a ‘ZDHC MRSL level 3 certificate’, a ‘Cradle-to-Cradle Material Health certificate’ (part of a full Cradle-to-cradle certification), a ‘ToxFMD Screened Chemistry certificate’ and a ‘Cradle-to-cradle Life Cycle Analyses (LCA)’ for the Zeology tanning product, Nera published an academic paper in Green Chemistry on the working mechanisms of the tanning agent. Nera uses these data sets to plan and realize further impact improvements for future Zeology developments.

Objective: Supporting the leather industry, tanneries, fashion, and automotive brands, with a sustainable and versatile alternative to chrome and GDA tanning.

Zeology – The sustainable and versatile alternative to chrome and GDA tanning

Lignin modified re-tanning agents

Objective: Improving the renewability and bisphenol reduction in phenolic Syntans

Biopolymers based on sugar beet pectins

Objective: Creating bio-based ingredients

Bio-based Polyurethanes

Objective: Creating bio-based ingredients

Biopolymers from LIFE Biopol

Objective: Creating bio-based ingredients

Optitan and Safetan range

Objective: Minimizing the environmental impact, while optimizing leather performance

Basetone White

Ti-Free

Objective: Eliminating hazardous substances from our product range

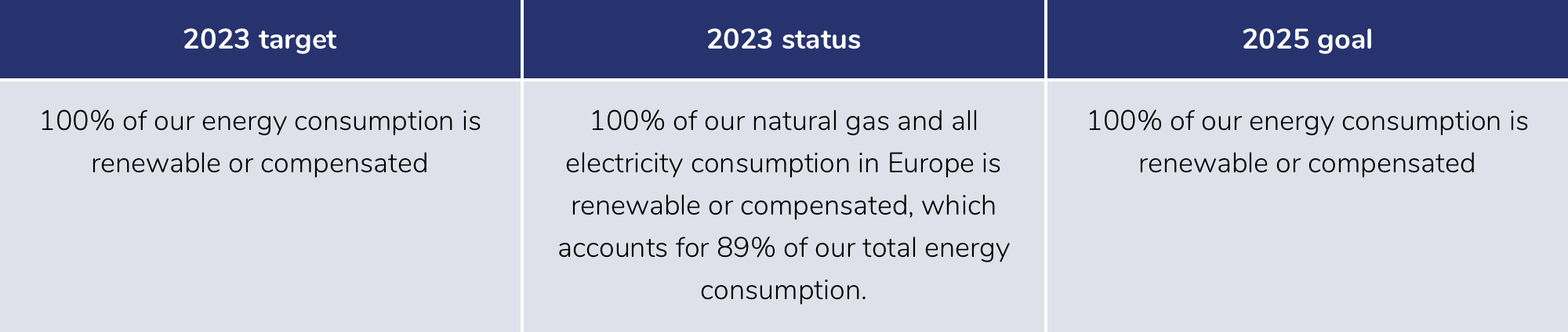

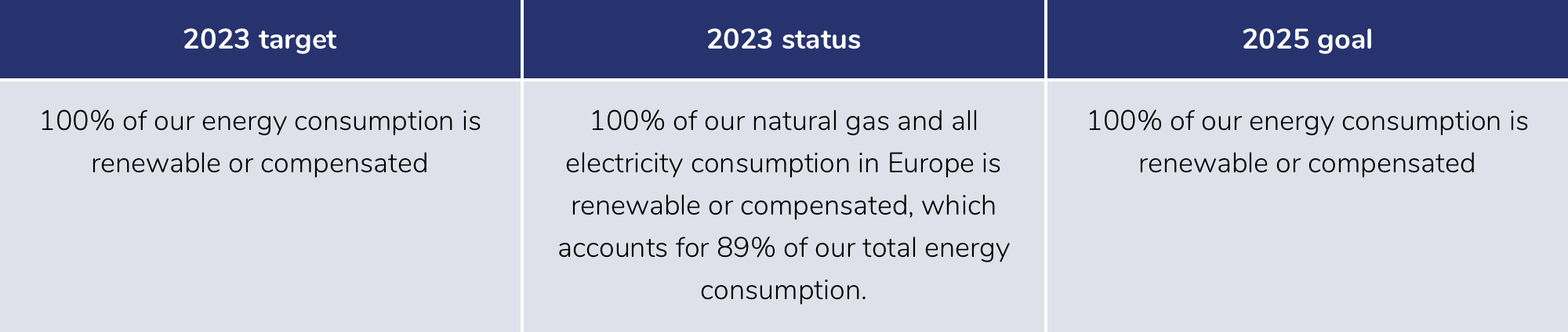

Royal Smit & Zoon exclusively relies on 100% certified sustainable energy for its factories and uses certification programs including the Gold Standard Verified Emission Reductions (VERs) to compensate (offset) where necessary.

The urgent need to combat climate change, expected EU and national regulations on energy consumption and Greenhouse Gas (GHG) emissions, and steeply increasing energy market prices, made us start a new round of energy reduction actions already in 2022. In 2023, we completed new investigations to identify additional opportunities for improving the energy efficiency of processes and equipment. Optimized production planning, process optimization of spray driers, replacing old electrical equipment with more energy-efficient new equipment and re-enforced attention to ‘good housekeeping’ measures resulted in further reductions in energy consumption. A detailed list of energy savings and/or reduction measures taken in 2023, are listed in Facts & Figures. Furthermore, results from the investigations will be used for setting up a multi-year energy reduction program.

So far, we did not yet find solutions for purchasing renewable energy or compensation for our Asia operations or for other fuels than natural gas, e.g. for forklifts. In 2024 we will proceed exploring options for this.

Our energy consumption is renewable or compensated

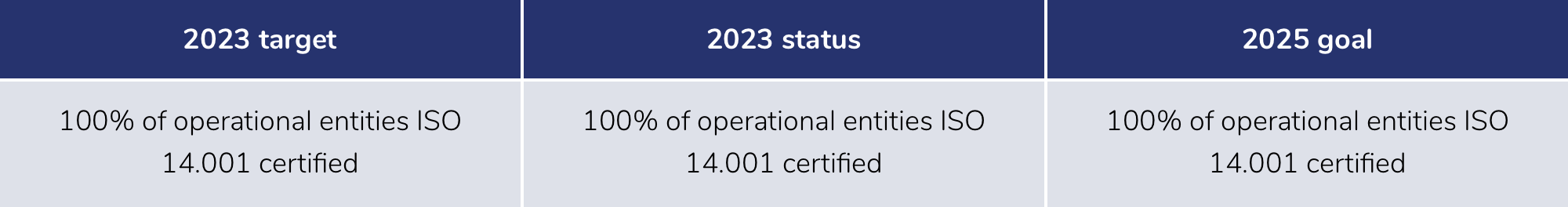

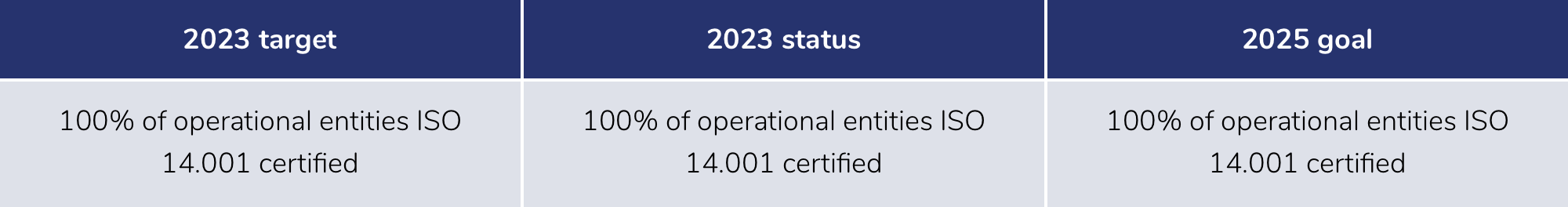

Already in 2022, our final production entity in India obtained ISO 14.001 certification. Based on this reputable certification, this means all our entities have world-class environmental management systems in place. Royal Smit & Zoon views the implementation of its environmental management system as a process of continuous improvement. According to the Plan-Do-Check-Act Cycle, the ISO 14.001 certification requires ongoing reviews of our practices, processes, and procedures, periodic internal or external audits to verify and check, and where needed – improved implementation.

All entities have world-class environmental management systems in place

UN SDG goals

We addressed UN SDGs 6, 8, 12, 13, and 17 and a series of our Double Materiality Matrix topics, including Chemical waste, Water & waste water treatment, Product stewardship, Sustainable product innovations & Circularity, Sustainable raw materials, Climate change.

In 2020, Royal Smit & Zoon completed the LIFE Biopol project and launched several new products with bio-based ingredients. In 2022 we already completed an upgrade of the original products to increase the production process to make it safer, as well as increasing the biobased content to 94% for the Biosyn AP 82L and Biosyn SC63L. In 2023, we continued the update, enriching the biobased portfolio with new products, such as BiPoltens S70 and BioPolicker SSC NEW.

In 2023, Zeology, the chrome, heavy metal and aldehyde free tanning agent based on modified zeolite, has experienced a further adoption. We witnessed a significant increase in the number of tanneries producing leather with Zeology, an increased number of leather producers offering Zeology leather to brands and Original Equipment Manufacturers (OEMs) and Zeology leather being presented at fairs or via their online channels (e.g., Puma; Tasman Tanning; Emma Safety Footwear; Ted Louise; Nuova ECOS; Vicenza Pelli). In addition, we saw an increasing demand from brands and OEMs requesting specifically for Zeology leather. In 2024, we anticipate the first car brands to launch Zeology tanned automotive leather in their vehicles. With this, Zeology is increasingly driving significant impact in making the leather value chain more sustainable. You can find more information on brand engagement under ‘Social’.

While the adoption of Zeology is progressing well, the landscape of leather tanning is undergoing rapid and transformative changes. As the demand for chrome free leather continues to grow, the European Chemicals Agency (ECHA) has increased legislative pressure on the traditional chrome free tanning agent GDA (also referenced to as glutardialdehyde or glutaral). ECHA recommended 4 the inclusion of GDA as a substance in Annex XIV of REACH (List of Substances subject to Authorisation), signalling expected restrictions on the production and application of the listed substances. By providing a sustainable solution as Zeology, we support tanneries, brands and OEMs in meeting market demands and anticipating upcoming legislations.

We understand that responsible procurement of raw materials is a crucial part of building a sustainable supply chain. This is why the alumina trihydrate (ATH) used to produce the zeolite for our tanning product Zeology meets the highest ESG standards and has been certified according to the Aluminium Stewardship Initiative (ASI) standards since 2022. This way Nera guarantees that all steps in our value chain from the bauxite mining until and including the production of zeolite comply with the ASI Performance Standard and the ASI Chain of Custody Standard. ASI standards address various ESG topics such as environmental impact, material stewardship, human and labour rights, and business governance. Next to working with zeolite from certified ATH, Nera has become a supporting member of the Aluminium Stewardship Initiative in 2023.

Sharing knowledge and evidence for our claims and being transparent are crucial aspects. For that reason, Royal Smit & Zoon/Nera focused on sharing information through our websites, whitepapers, organizing Masterclasses, and obtaining certifications proving Zeology is a sustainable solution. Besides ESG related certifications such as a ‘ZDHC MRSL level 3 certificate’, a ‘Cradle-to-Cradle Material Health certificate’ (part of a full Cradle-to-cradle certification), a ‘ToxFMD Screened Chemistry certificate’ and a ‘Cradle-to-cradle Life Cycle Analyses (LCA)’ for the Zeology tanning product, Nera published an academic paper in Green Chemistry on the working mechanisms of the tanning agent. Nera uses these data sets to plan and realize further impact improvements for future Zeology developments.

% based on volume sold

UN SDG goals

We addressed UN SDGs 6, 8, 12, 13, and 17 and a series of our Double Materiality Matrix topics, including Chemical waste, Water & waste water treatment, Product stewardship, Sustainable product innovations & Circularity, Sustainable raw materials, Climate change.

Please swipe to view full table

Already in 2022, our final production entity in India obtained ISO 14.001 certification. Based on this reputable certification, this means all our entities have world-class environmental management systems in place. Royal Smit & Zoon views the implementation of its environmental management system as a process of continuous improvement. According to the Plan-Do-Check-Act Cycle, the ISO 14.001 certification requires ongoing reviews of our practices, processes, and procedures, periodic internal or external audits to verify and check, and where needed – improved implementation.

All entities have world-class environmental management systems in place

Please swipe to view full table

Royal Smit & Zoon exclusively relies on 100% certified sustainable energy for its factories and uses certification programs including the Gold Standard Verified Emission Reductions (VERs) to compensate (offset) where necessary.

The urgent need to combat climate change, expected EU and national regulations on energy consumption and Greenhouse Gas (GHG) emissions, and steeply increasing energy market prices, made us start a new round of energy reduction actions already in 2022. In 2023, we completed new investigations to identify additional opportunities for improving the energy efficiency of processes and equipment. Optimized production planning, process optimization of spray driers, replacing old electrical equipment with more energy-efficient new equipment and re-enforced attention to ‘good housekeeping’ measures resulted in further reductions in energy consumption. A detailed list of energy savings and/or reduction measures taken in 2023, are listed in Facts & Figures. Furthermore, results from the investigations will be used for setting up a multi-year energy reduction program.

So far, we did not yet find solutions for purchasing renewable energy or compensation for our Asia operations or for other fuels than natural gas, e.g. for forklifts. In 2024 we will proceed exploring options for this.

Our energy consumption is renewable or compensated

Biopolymers from LIFE Biopol

Objective: Creating bio-based ingredients

This white pigment is formulated with insoluble inorganic and non-harmful substances and is 100% free of TiO2. The technology of Basetone White Ti-free enables reaching very high covering power and excellent physical fastness properties without losing refraction-index with a consequent great white intensity. Due to its special formulation, this pigment fits perfectly when used on metal-free white leather following ISO specification 15115: 2019.

Basetone White

Ti-Free

Objective: Eliminating hazardous substances from our product range

In 2020 and 2021, the Optitan range was introduced to address the need for products with low formaldehyde emissions from leathers. From 2022 onwards, the need for low bisphenol products grew influenced by the upcoming European legislation through ECHA. By the end of 2023, the proposed restrictions were temporarily withdrawn. In 2024, a new proposal from the German BAUA is expected on the restriction of use of bisphenols in the chemical industries. As Royal Smit en Zoon we anticipate that the initial step will involve ensuring products to have less than 500ppm, followed a further reduction to <10ppm of the sum of bisphenols over a two year transition period. The Optitan and Safetan ranges were expanded in 2023 with the launch of Optitan LP 161, Optitan MP 424L and Safetan LD 006 and Safetan DK 007. Developing formaldehyde free products alongside with the Optitan range will ensure Royal Smit & Zoon maintains a future proof product portfolio.

Optitan and Safetan range

Objective: Minimizing the environmental impact, while optimizing leather performance

Royal Smit & Zoon launched SMITFIX BIO 100 (Bio-Based Polyurethanes for basecoat) and SMITFIX M 156 & SMITFIX G 126 in 2022, which are two partially bio-based polyurethanes. Polyurethanes are among the most versatile and commonly used polymers in the world. With current technology, it is possible to move to partially renewable and sustainable bio-based carbon content. This is feasible by adding bio-based carbon content and reducing CO2 emissions by using bio polyol.

Bio polyol or natural oil polyol (NOP) is synthesized from various vegetable oils and other renewable sources, which are a by-product in the pulp and paper industry. Bio polyol offers a higher bio-based carbon content and a reduction in CO2 emissions.

Bio-based Polyurethanes

Objective: Creating bio-based ingredients

Royal Smit & Zoon launched its new 100% biobased and readily biodegradable product during 2022. This circular innovation was achieved in cooperation with Wageningen University Food & Biobased Research, Royal Cosun, and other partners in a research consortium. The primary aim of this development was to substitute fossil fuel-based and non-biodegradable polymers in products for the wet-end production process. This biopolymer technology based on sugar beet pectin has been proven for its technical performance in tannery settings. Leather characteristics are positively influenced, especially its color intensity. Royal Smit & Zoon perceives this as an achievement of a technological milestone in using partnerships to advance innovation that fits with future chemistry, the vision of our company and customer expectations. Further exploitation of knowledge gained will continue in the coming years.

Biopolymers based on sugar beet pectins

Objective: Creating bio-based ingredients

During 2023, Royal Smit & Zoon continued to make a full industrial-scale production of the Smit Biotan XP 01L, which is a chemical incorporating lignins in phenolic re-tanning agents. The aim is to increase the renewable content by partially replacing phenol with industrial lignins and possibly improve the biodegradability of phenolic syntans. The emissions profile on phenol, formaldehyde, and bisphenols of this novel product is excellent, and Biotan XP 01L combines the benefits of a phenolic re-tanning agent with bisphenol levels below the current detection limit of < 10 ppm. The leather performance of this partially biobased product is comparable to traditional retanning chemicals built from fossil fuels. The developments are currently focusing on diversifying the type of lignins as well as broadening the product portfolio. Especially having very low bisphenol level (<10 ppm) products, increased renewable content.

Lignin modified re-tanning agents

Objective: Improving the renewability and bisphenol reduction in phenolic Syntans

Objective: Supporting the leather industry, tanneries, fashion, and automotive brands, with a sustainable and versatile alternative to chrome and GDA tanning.

Zeology – The sustainable and versatile alternative to chrome and GDA tanning

Please swipe to view full table

Innovation is at the heart of our strategy, and we are on track to develop best-in-class chemistry. In recent years, several new patents have been registered, updates to our Product Passport have been made, and experiences have been widened with techniques like Life Cycle Assessments, wastewater guidelines, biodegradability, compostability, and circularity in general. This has led to several innovations in recent years that are currently being marketed. A selection is described below.

Develop innovative chemistry and leather-making processes to increase circularity

Please swipe to view full table

Our product range is ZDHC compliant and certified

Royal Smit & Zoon has been an active contributor to the ZDHC (Zero Discharge of Hazardous Chemicals) Foundation since 2018. Our Partnership acknowledges our joint commitment to uphold the highest environmental and social responsibility standards throughout our operations. Our product development strictly adheres to the ZDHC specifications and reflects our dedication to sustainable chemical management.

Already in 2019, our key product range was certified according to the ZDHC Conformance Level 3. In 2023, our certificates were renewed through the bi-annual process and fully available on our website. Our annual performance is mostly unchanged and remains slightly below the 2023 target of 85%. This outcome is attributed to market developments experienced over the past couple of years, the pending certification of new products, and the current absence of certification of our production site in India. In response, efforts are underway to prepare our Indian site for certification in 2024 and align excellence across our factories worldwide.

Due to tighter regulations and customer requests, Royal Smit & Zoon expanded its own Manufacturing Restricted Substance List (MRSL) considering the ZDHC MRSL, the Candidate List of Substances of Very High Concern (SVHC), the Authorization List (REACh Appendix XIV), and the Restrictions List (REACh Appendix XVIII). This ultimately means substances are banned from being intentionally used during the manufacturing process. Our MRSL is updated at least once a year. Furthermore, we are voluntarily phasing out unwanted substances not (yet) on the list of restricted substances. This decision is based on the substance hazards, market information, or ESG ambitions and regulatory insights. Through these initiatives, we actively contribute to a more sustainable and responsible chemical management in our supply chain.

Here, we describe our commitments towards the environment, focusing on our ESG Roadmap 2025 commitments.

Achievements

Environment