Here we describe our commitments towards the environment, focussing on our 2025 ESG Roadmap commitments.

Achievements

Environment

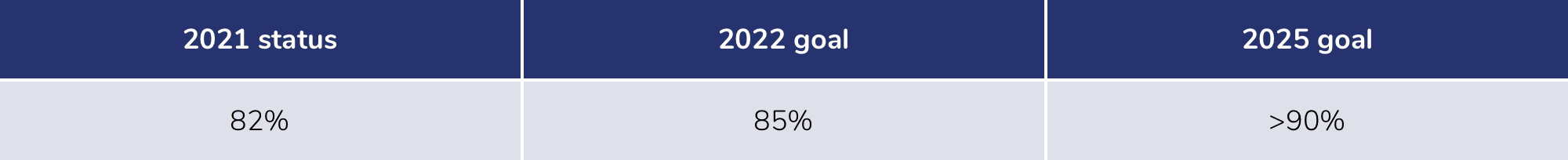

Our product range is ZDHC compliant and certified

Royal Smit & Zoon has been a contributor to the ZDHC (Zero Discharge of Hazardous Chemicals) since 2018 and strongly supports their mission to create a supply chain towards safer chemistry. In 2019, our first products were certified according to the ZDHC Conformance Level 3 and since then we included our key range in this program.

The basis for future compliance is our own internal Restricted Substances List (RSL). This is a list of substances that we do not allow in any of our products. A steering group reviews and updates the Royal Smit & Zoon RSL annually, taking into account the following sources and criteria: Candidate List of Substances of Very High Concern (ECHA); Authorization List (Appendix XIV of REACh); List of Restrictions (Appendix XVII of REACh); Manufacturing Restricted Substances List (MRSL of ZDHC). The Royal Smit & Zoon RSL remained unchanged, apart from changes in the official EU lists, which were, of course, included. Additionally, we are proactively phasing out unwanted substances that are not (yet) on the list of restricted substances. Substances to be phased out are selected based on their hazard and on information from the market.

Innovation is the heart of our strategy and we are on track to develop best-in-class chemistry. In recent years, several new patents have been registered, updates of our Product Passport have been made, and experiences have been widened with techniques like Life Cycle Assessments, wastewater guidelines, biodegradability, compostability, and circularity in general. This has led to several innovations in recent years that are currently being marketed. A selection is described below.

Develop innovative chemistry and leather-making processes to increase circularity

Zeology, the sustainable tanning concept

Objective: Support the tanneries & brands in replacing chrome and GDA tanning, targeting a sustainable leather value chain.

Lignin modified re-tanning agents

Objective: Improving the renewability

Biopolymers based on sugar beet pectins

Objective: Creating bio-based ingredients

Bio-based Polyurethanes

Objective: Creating bio-based ingredients

Optitan

Objective: Minimizing the environmental impact, while optimizing leather performance

Basetone White

Ti-Free

Objective: Eliminating hazardous substances from our product range

Micro-Fresh ®

Objective: Providing a unique solution to a world with COVID-19

DesertSpring

Objective: Creating a sustainable tanning concept and superior leather performance

Royal Smit & Zoon is using certification programs including the Gold Standard Verified Emission Reductions (VER’s) and the purchase of certificates of Sustainable Energy for all of its factories.

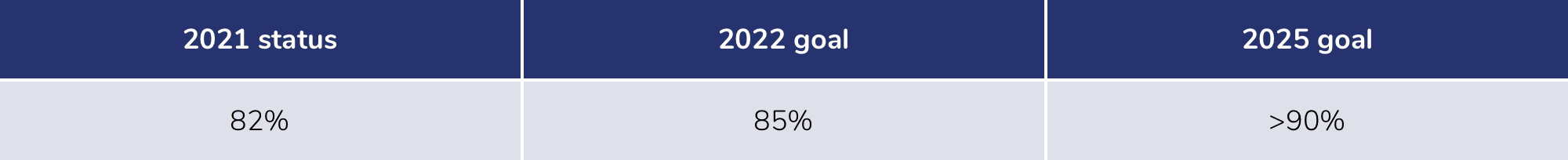

Our energy consumption is renewable or compensated

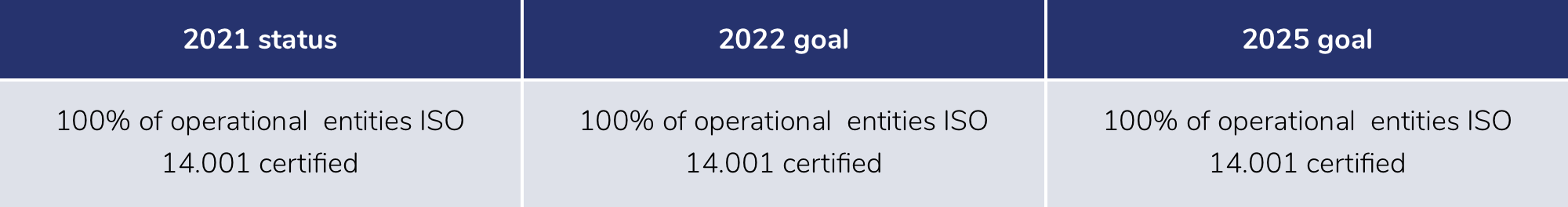

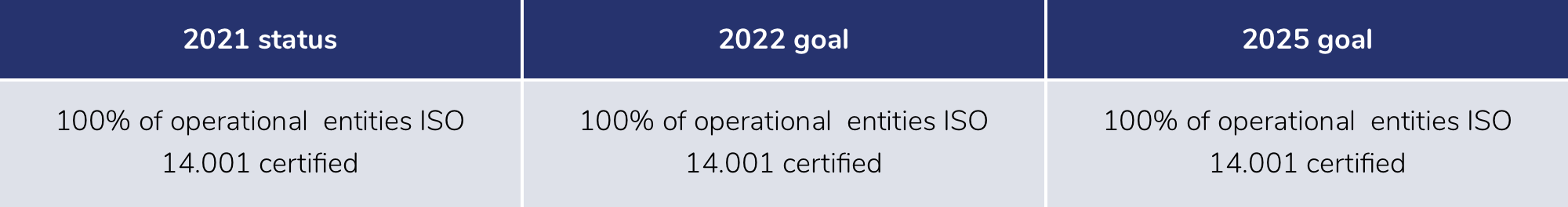

In 2021, our production entities in India and Italy obtained ISO 14.001 certification, which results in all our production entities being certified.

All entities have world-class environmental management systems in place

UN SDG goals

We adressed UNG SDG goals 6,8,12,13,17, and a series of Materiality Matrix topics, including Occupational Health & Safety, Effluents & Waste, Water & Effluents, Materials, Environmental Compliance, Economic Performance, Customer Health & Safety Emissions, Energy.

UN SDG goals

We adressed UNG SDG goals 6,8,12,13,17, and a series of Materiality Matrix topics, including Occupational Health & Safety, Effluents & Waste, Water & Effluents, Materials, Environmental Compliance, Economic Performance, Customer Health & Safety Emissions, Energy.

Please swipe to view full table

In 2021, our production entities in India and Italy obtained ISO 14.001 certification, which results in all our production entities being certified.

All entities have world-class environmental management systems in place

Please swipe to view full table

Royal Smit & Zoon is using certification programs including the Gold Standard Verified Emission Reductions (VER’s) and the purchase of certificates of Sustainable Energy for all of its factories.

Our energy consumption is renewable or compensated

Nera Tanning, in cooperation with Enviu and SN Botanicals, is developing a revolutionary, circular, metal- and chrome-free tanning concept based on the extract of the Sea buckthorn plant. The concept is called ‘DesertSpring’; it is bringing back life to desert grounds while making the leather value chain more sustainable. DesertSpring is still in the conceptional development phase.

DesertSpring

Objective: Creating a sustainable tanning concept and superior leather performance

Royal Smit & Zoon became the distributor for Micro Fresh® in the leather industry. Micro-Fresh® developed materials such as leather with an anti-bacterial, anti-viral, and anti-fungal performance. Micro Fresh® started as an innovative formula that solved the problem of bacterial growth during the transit of retail goods. 15 years later, their multi-award-winning technology is used by major retailers and manufacturers around the world to achieve lifetime product freshness. Micro Fresh® is an invisible treatment that can be applied at the point of finishing as a viral treatment.

When leather is treated with Micro Fresh® it takes the survival time of COVID-19 from 24-48 hours to two hours. There is also no transmission from the anti-viral coated leathers to other surfaces two hours after contamination of the leathers.

Micro-Fresh ®

Objective: Providing a unique solution to a world with COVID-19

This white pigment is formulated with insoluble inorganic and non-harmful substances and is 100% free of TiO2. The technology of Basetone White TI-Free allows reaching very high covering power and excellent physical fastness properties without losing refraction-index with as a consequent great white intensity. Due to its special formulation, this pigment fits perfectly when used on metal-free white leather following ISO specification 15115: 2019.

Basetone White

Ti-Free

Objective: Eliminating hazardous substances from our product range

In 2020, the Optitan range was introduced. In 2021, the whole range was updated and assessed for bisphenols and will allow for leather that meets the upcoming bisphenol requirements.

Optitan

Objective: Minimizing the environmental impact, while optimizing leather performance

Royal Smit & Zoon has launched CODY PUR BIO 100 and CODY PUR BIO 200 which are two partially bio-based polyurethanes. Polyurethanes are among the most versatile and commonly used polymers in the world. With current technology, it is possible to move to partially renewable and sustainable bio-based carbon content. One of the components of polyurethanes is always a polyol. In our innovation, we are using bio polyol instead of fossil based.

Bio polyol or natural oil polyol (NOP) is synthesized from various vegetable oils and other renewable sources, which are a by-product in the pulp and paper industry. Bio polyol offers a higher bio-based carbon content and a reduction in CO2 emissions in the supply chain.

Bio-based Polyurethanes

Objective: Creating bio-based ingredients

At the end of 2021, Royal Smit & Zoon launched its new 100% biobased product BioMax BP 088L. This is the result of the cooperation with Wageningen Food & Biobased Research and Royal Cosun. The BioMax BP 088L serves as a substitute for fossil fuel-based and non-biodegradable polymers in chemicals for the wet-end production process. BioMax BP 088L also positively influences the characteristics of finished leather, especially its color intensity.

Biopolymers based on sugar beet pectins

Objective: Creating bio-based ingredients

In 2021, Royal Smit & Zoon made a small industrial-scale production of a product chemically incorporating lignins in phenolic re-tanning agents. The aim is to increase the renewable content by partial replacement of phenol with industrial lignins and possibly improve the biodegradability of phenolic syntans. This small-scale production proved the feasibility of the technology and reconfirmed the leather performance of the pilot product. In addition, the pilot product is very low in free phenol and is free of formaldehyde, displays very low bisphenol emissions, and has increased renewability characteristics. The launch is expected in 2022, after having incorporated the learnings from the small industrial scale productions.

Lignin modified re-tanning agents

Objective: Improving the renewability

In 2021, Nera, a Royal Smit & Zoon brand, further introduced its sustainable tanning concept Zeology to the leather supply chain. Zeology is a truly sustainable alternative to existing tanning agents. It is zeolite-based and therefore chrome-free, heavy metal-free, and aldehyde-free.

Zeology was developed to provide a sustainable alternative to existing tanning agents. Introducing Zeology is another step towards a more sustainable leather value chain. In line with this, Zeology was awarded the ToxFMD Screened Chemistry certification.

What makes Zeology unique, compared to both traditional tanning agents and other existing sustainable alternatives, is that it delivers both sustainability benefits and superior leather performance. Zeo White, the Zeology-tanned leather intermediate, is unsurpassed in characteristics such as grain tightness, physical leather properties, lightfastness, and heat resistance. In addition, its bright white color enables more whiter leather, as well as lighter and brighter colors than were ever possible before. At the time of writing, Zeology has been adopted by a widegrowing number of tanneries and brands, including Anya Hindmarch and PUMA, that focus on creating sustainable product lines with leathers that are biodegradable and compostable. With this, Zeology is already driving a significant impact in making the leather value chain more sustainable.

Zeology, the sustainable tanning concept

Objective: Support the tanneries & brands in replacing chrome and GDA tanning, targeting a sustainable leather value chain.

Please swipe to view full table

Innovation is the heart of our strategy and we are on track to develop best-in-class chemistry. In recent years, several new patents have been registered, updates of our Product Passport have been made, and experiences have been widened with techniques like Life Cycle Assessments, wastewater guidelines, biodegradability, compostability, and circularity in general. This has led to several innovations in recent years that are currently being marketed. A selection is described below.

Develop innovative chemistry and leather-making processes to increase circularity

Please swipe to view full table

Our product range is ZDHC compliant and certified

Royal Smit & Zoon has been a contributor to the ZDHC (Zero Discharge of Hazardous Chemicals) since 2018 and strongly supports their mission to create a supply chain towards safer chemistry. In 2019, our first products were certified according to the ZDHC Conformance Level 3 and since then we included our key range in this program.

The basis for future compliance is our own internal Restricted Substances List (RSL). This is a list of substances that we do not allow in any of our products. A steering group reviews and updates the Royal Smit & Zoon RSL annually, taking into account the following sources and criteria: Candidate List of Substances of Very High Concern (ECHA); Authorization List (Appendix XIV of REACh); List of Restrictions (Appendix XVII of REACh); Manufacturing Restricted Substances List (MRSL of ZDHC). The Royal Smit & Zoon RSL remained unchanged, apart from changes in the official EU lists, which were, of course, included. Additionally, we are proactively phasing out unwanted substances that are not (yet) on the list of restricted substances. Substances to be phased out are selected based on their hazard and on information from the market.

Here we describe our commitments towards the environment, focussing on our 2025 ESG Roadmap commitments.

Achievements

Environment